A complete guide to the rubber insert molding process

A complete guide to the rubber insert molding…

XTmade Wire EDM is a premier wire-cut EDM outsource supplier and provider of wire EDM services. Our team partners with a broad cross section of industries to supply high-precision prototypes, medium-volume runs, and long-term, high-volume EDM component production services.

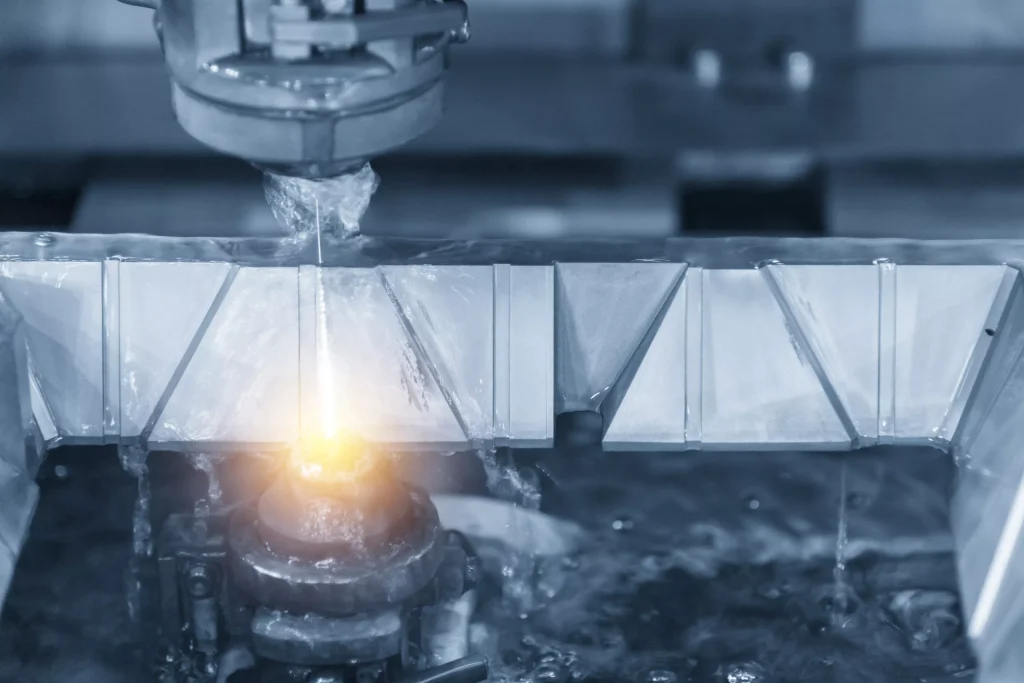

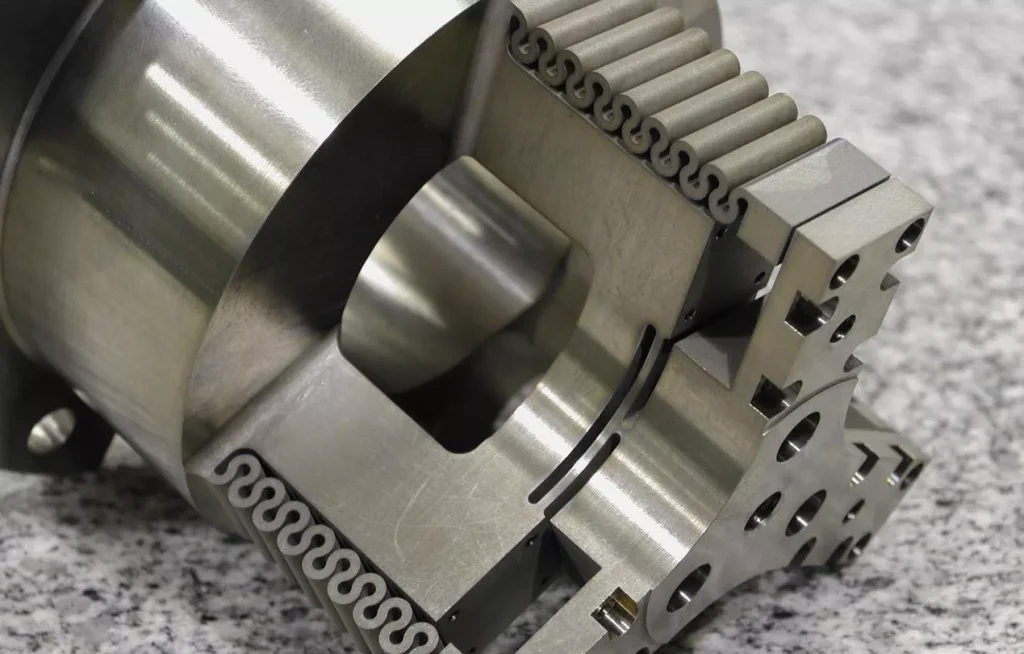

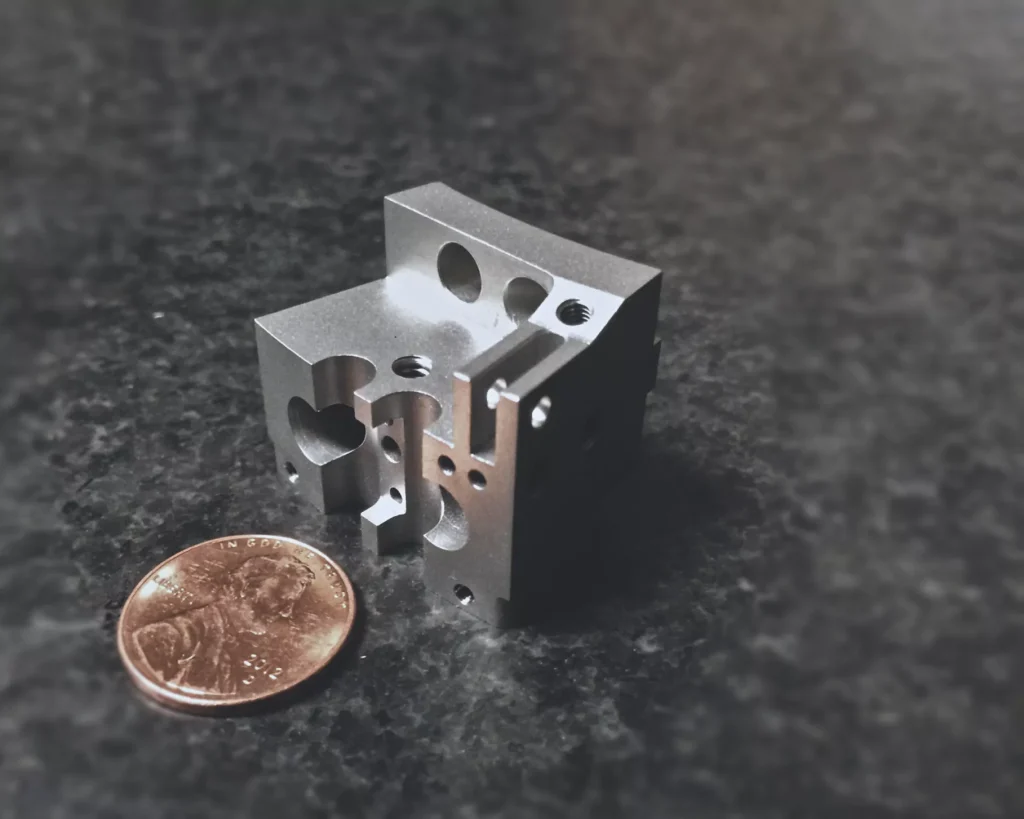

XTmade manufactures high-quality wire-cut parts in days, not months. Our network includes hundreds of shops with wire-cut capabilities, giving you virtually unlimited ability to manufacture both simple and complex parts. As a versatile precision component manufacturer, XTmade offers EDM using both wire and hole cutter EDM equipment. Electrodischarge machining (EDM) is a unique machining method that relies on an electrical charge rather than mechanical wear to remove material. In wire cutting, different wire diameters can be used to achieve the right balance of precision and speed for a specific application. Our wire EDM machines can hold extremely tight tolerances of around ±0.0002 inches, and can accurately cut holes between 0.020 inches and 0.12 inches using our Mitsubishi hole cutters. Our wire EDM equipment features 4 cutting axes with a maximum taper of 17° at 4 inches of material thickness.

Wire electrical discharge machining cuts or shapes metal workpieces using a thin electrode wire controlled by a CNC. The wire is charged with electric current, and sparks form between the wire and the workpiece, melting its surface. The cutting wire never contacts the workpiece directly, so there’s no distortion in the cutting path or the shape of the material.

Compared to other precision metal cutting processes, wire EDM has many advantages:

For metal parts that require cutting through the full thickness of the raw material, wire EDM is an option. Wire EDM services are ideal for projects that require complex tolerances, materials that are too brittle to stamp, and where material stress and heating are limited. Our engineers and machinists have extensive knowledge of best EDM machining practices and materials as they apply to many different industries and applications, including but not limited to:

Combining our EDM manufacturing capabilities with our other cutting, forming and machining capabilities will simplify multi-process projects. Whether your needs are for a single, one-of-a-kind component or ongoing production quantities, consider choosing XTmade for your wire EDM needs as a single-source supplier.

A complete guide to the rubber insert molding…

A guide to on-demand manufacturing for low-volume injection…

Understanding the Design and Application of ABS Plastic…

Don’t miss our future updates! Get Subscribed Today!