A complete guide to the rubber insert molding process

A complete guide to the rubber insert molding…

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 1 business day.

Injection molding and all related services are performed by XTmade. Our offers a wide range of injection molding services to help our customers with their troubleshooting and production needs.

All samplings and production runs are setup based on scientific injection molding principles.

Our team of plastics engineers has extensive real-world experience with injection molding, product development, mold design and part design, and quality control.

Our presses range from 3 U.S. Tons to 330 U.S. Tons, and they support shot sizes from 0.1 oz to 20.86 oz.

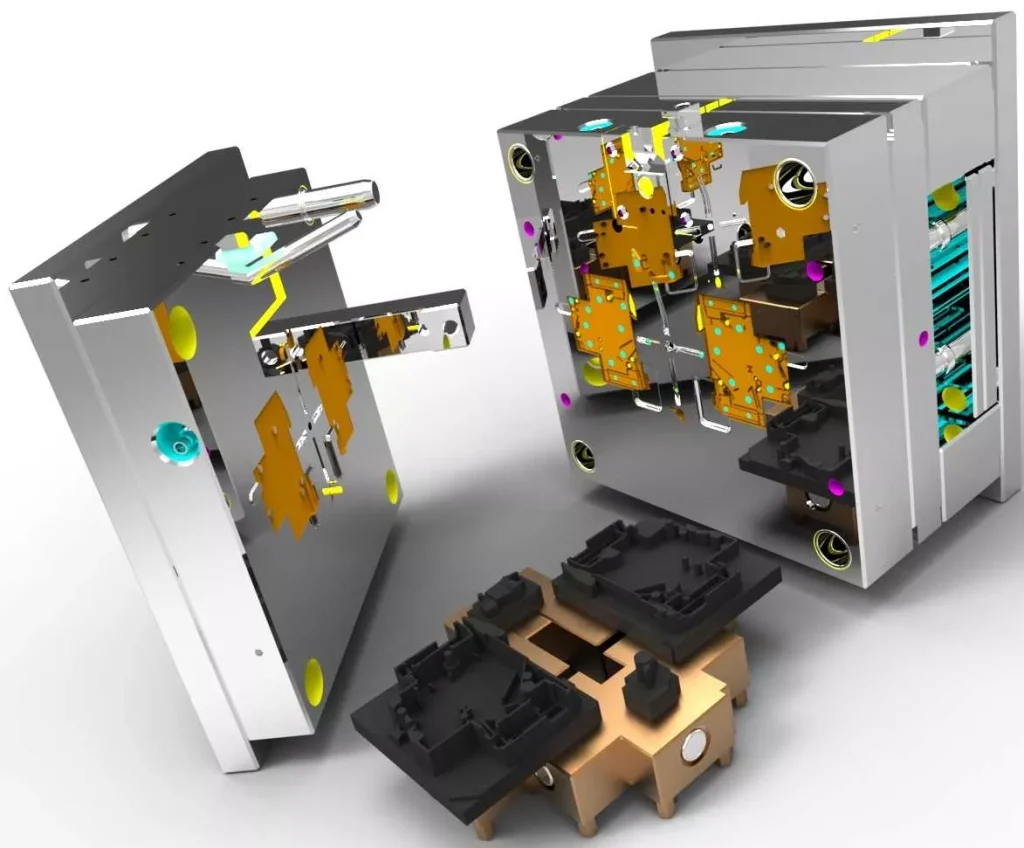

Our core competency in mold manufacturing lies in the following three stages:

We can fabricate injection molding tooling in aluminum — ideal for rapid low-volume prototyping — or tool steel. Molds adhere to SPI mold classification, which specifies the durability of tooling and for how many cycles it is suitable.

Standard injection mold tooling is defined by classes from Class 105 (prototype) to Class 101 (high volume production). These mold classes help manage expectations for both customers and suppliers on the overall tool requirements and scope.

Under 500 cycles. Prototype only. This mold will be constructed in the least expensive manner possible to produce a minimal quantity of prototype parts. Class 105 molds are also known as Class V tools.

Example: a one-and-done market test of 100 molded units.

Under 100,000 cycles. Low production mold. Use only for limited production, preferably with non-abrasive materials. Low to moderate price range. Class 104 molds are also known as Class IV tools.

Example: Aluminum or MUD tooling, SPI B-3 finish, hand-loaded cores, and limited re-runs.

Under 500,000 cycles. Medium production mold. This is a very popular mold for low to medium-production needs. Most common price range. Also known as a Class III tool.

Example: Aluminum or steel tooling, automated lifts or slides, multiple re-runs with batches between 1,000-5,000 units.

Medium to high production tooling, suitable for abrasive materials or parts requiring close tolerance. This is a high-quality, reasonably high-priced mold. Class 102 Molds are also known as Class II tools.

Example: Steel tooling with an SPI A-2 finish, automated slides, scheduled production cycles.

Over 1,000,000 cycles. They are engineered for extremely high production. This is the highest-priced mold and is made with only the highest-quality materials. Class 101 molds are also known as Class I tools.

Example: Multiple-cavity steel tooling with full automation and overnight production work centers for dedicated part manufacturing.

We have wide selection of more than 100 thermoplastic and thermoset materials. And if you’re looking for alternative material options, check out our guide to resin substitutes for ABS, PC, PP, and other commonly molded plastics.

Plastic injection molding is the process of filling a mold tool with liquid plastic resin under great pressure. The tool may comprise a single cavity or hundreds of cavities in order to make indefinite numbers of parts. Once the mold tools have been carefully designed and manufactured, the molding process consists of the following basic steps:

Heating plastic to reform it and insert a component (e.g., a threaded insert).

Engraving text or a design with a laser.

Applying an ink-based, 2D design to a 3D surface

Applying primer, top coat, EMI (copper) paint, in both standard and Pantone colors.

Joining or reforming thermoplastics with a high-frequency welder

Injection molding is the process of injecting molten plastic into a mold cavity, rapidly cooling it, then ejecting the solidified plastic part. It is the most widely used manufacturing process for plastic parts and the most affordable route to mass production. Once the metal mold or tooling has been made, hundreds, thousands, or millions of plastic duplicate parts can be made in a short timeframe, with the effective cost-per-part reducing with each additional molding as the cost of the mold is amortized. Injection molding is compatible with a very wide range of materials — including thermoplastics, thermosets, and even metals — which can be easily mixed with color pigments and other additives to tweak the function and appearance of the moldings. Furthermore, the injection molding process offers excellent consistency between units, as the tooling remains constant throughout.

At XTmade, we offer a range of injection molding services, from affordable low-volume prototyping to part production, using thermoplastics, thermosets, or metals. Our team of experienced molding specialists can guide you to the right solution, whether you need rapid aluminum tooling for a fast prototype or a more durable solution for larger production runs. Unlike many molding companies, we do not specify a minimum order quantity.

You can rest assured your mold will be fabricated to the highest quality, to create

injection molded parts that meet your exact specifications.

A complete guide to the rubber insert molding…

A guide to on-demand manufacturing for low-volume injection…

Understanding the Design and Application of ABS Plastic…

Don’t miss our future updates! Get Subscribed Today!