A complete guide to the rubber insert molding process

A complete guide to the rubber insert molding…

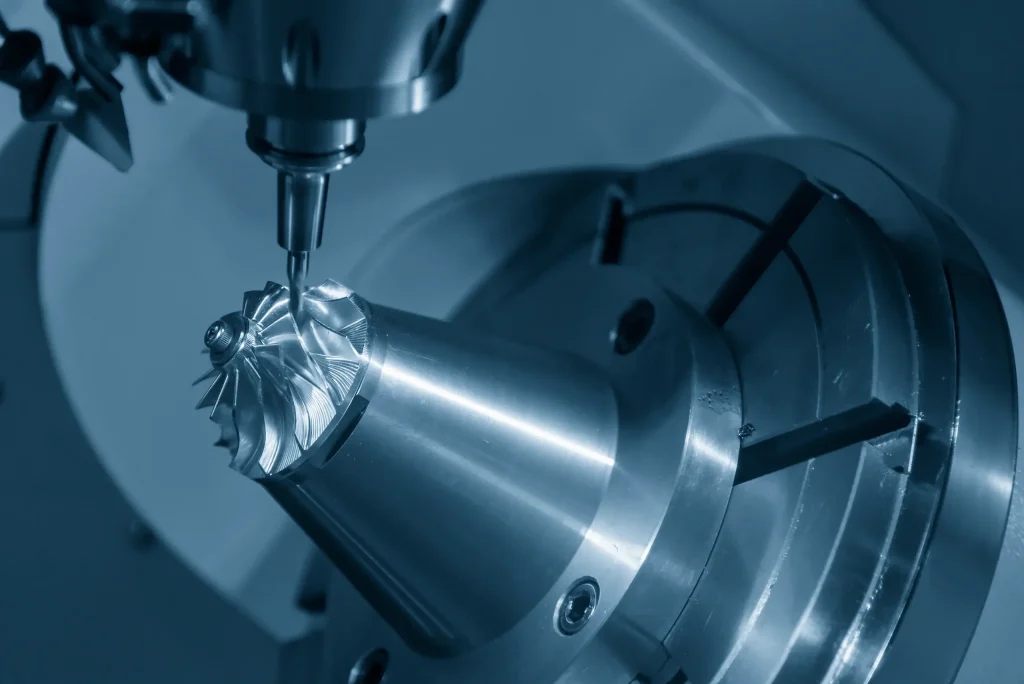

Get high-precision production parts with extremely complex geometries at an affordable price with our custom 5-axis CNC machining services. World-class 5-axis CNC machines produce precision parts quickly and to tight tolerances.

At our CNC machine shop, we specialize in providing high-quality 5-Axis machining services that are tailored to meet the unique needs of our clients. Whether you need custom parts for aerospace, automotive, or medical applications, we have the expertise and equipment to deliver superior results.

Our team of experienced machinists and engineers work closely with our clients to understand their specific needs and requirements. From the initial design phase to the final product, we are committed to providing exceptional service and quality.

In addition to our 5-Axis machining capabilities, we also offer a range of other machining services, including prototyping, rapid prototyping, and EDM machining. With our state-of-the-art equipment and advanced technology, we are able to deliver efficient, cost-effective solutions that meet the highest standards of quality and precision.

With 5 axis machining services, we can machine extreme precise and accurate complex geometries . For parts with extremely complex and multi-faceted designs, our advanced five-axis machines can perform efficient and flexible machining through five-axis linkage,allowing a shorter, stronger cutting tools to improve stability, stay precision and achieve good surface quality. Tik Precision provides 5 axis CNC machining parts for global customers in China, industries fields covering aerospace, automotive, shipbuilding, machinery, medical, energy, electronics and other industries. Whether it is metal or plastic materials, whether it is prototyping or small batch production, our factory’s advanced equipment can meet your needs. We have the machining capability to achieve precision up to 0.002mm tolerance, and can provide a complete test report. You can rest assured to entrust the project to us.

3+2 axis is another form of 5 axis CNC machining. in which the machine can only move on the 4th and 5th axes (adjusting the angle of the cutting tool) when the cutting tool isn’t moving along the X, Y and Z axes. This form of 5-axis machining is generally slower than simultaneous 5-axis CNC, but creates more rigid parts and longer tool life.

Simultaneous (or continuous) 5-axis CNC machining is an advanced form of 5-axis machining in which the machine can continuously adjust without interruption, enabling movement in five axes. Synchronous 5-axis CNC is very fast because the cutting tool moves without interruption.

The difference between 3-Axis and 5-Axis CNC machining lies in their capabilities and the level of precision they offer. 5-axis CNC machining is considered the pinnacle of computer numerical control technology, revolutionizing the manufacturing landscape. Unlike 3-axis machines that control the machine tool along the X, Y, and Z linear axes, 5-axis machining adds two additional axes of rotation. This advanced technique allows for the creation of uniquely shaped parts with unparalleled precision.

One key advantage of 5-axis CNC machining is its ability to perform complete inspections for size analysis of materials through 5-axis positioning machining. This comprehensive analysis contributes to the production of more accurate components, meeting the highest quality standards.

In contrast to traditional 3-axis and 4-axis machining options, 5-axis machining offers unmatched versatility. By machining a component from three axes simultaneously, complex part production becomes achievable, resulting in improved efficiency and reduced production time.

XTmade has expanded its subtractive manufacturing and machining services with large 5-axis CNC machines to better provide robust electronic device protection in your most demanding applications. Molds are designed and manufactured to match your end product form factor and can be used with thermoset epoxies, polyurethanes, or silicones to provide heat, chemical, shock/impact and abrasion resistance, and FIPS protection for your electronic devices.

Boring, broaching, counterboring, countersinking, cutting, drilling, facing, gear hobbing, internal forming, knurling, milling, parting, pocketing, profiling, reaming, spline, tapping, threading (external, internal), turning (contour, form, taper, straight), and thread milling

With advanced manufacturing technology and rich experience, our 5 axis machining service team can make your unique prototypes and components from various metals and engineering plastics. We provide quotes for more than 100 metal and plastic materials and provide material reports.

XTmade offers a large number of surface treatments available to improve the surface quality of 5 axis machining service parts. Applying these finishes according to your parts’s usage,we can effectively improve the part’s appearance, surface roughness, hardness, corrosion resistance and more. Below are some of our commonly used surface preparation applications.

The cutting tool on a 5-axis CNC machining center can move along five axes instead of the usual three. Compared to a 3-axis CNC machine where the spindle can move up and down, side to side, and back and forth, a 5-axis machine has two other axes at work: the table swings from side to side on two different axes, or the spindle itself rotate on an axis. This allows the cutting tool to approach the workpiece from an infinite number of angles, remove excess material, and create parts with highly complex shapes.

5-axis CNC machining reduces the number of setups required: Machinists don’t have to manually flip the workpiece because cutting tools can simply reach more positions. This makes the entire machining process very fast.

By investing in our 5 Axis CNC machining services our customers experience a range of benefits, improving manufacturing output in a measurable way.

5-axis machining provides greater precision and speed for the most complex parts. As an industry-leading provider of reliable 5-axis CNC machining services, XTmade can provide high-quality machined parts that meet the needs of a variety of industries. To learn more about our 5-axis machining capabilities, or to get started on your next machining project, contact the experts at XTmade today.

A complete guide to the rubber insert molding…

A guide to on-demand manufacturing for low-volume injection…

Understanding the Design and Application of ABS Plastic…

Don’t miss our future updates! Get Subscribed Today!