Manufacturing Made Easy

Rapid Prototyping Services

We guarantee consistent quality for prototypes and end-use parts, whether produced in-house or through one of our proven manufacturing partners. Do you need parts as quickly as possible to validate a project?

From 1 to 100,000 parts, Global Delivery

Rapid Prototyping With Xtmade

Xtmade’s rapid prototyping services can help you turn your concepts into reality. Our rapid prototyping team will work with you to identify the prototyping services (injection molding, 3D printing, CNC machining, etc.) that meet your requirements and provide you with the parts you need in just a few days.

Whether you need a first experience, a fully functional, testable product, manufacturability testing, or another type of project, Xtmade has you covered. Our prototyping services use advanced manufacturing technologies and techniques to turn your ideas into reality. Even if you have no engineering experience, you can bring us your concepts and our rapid prototyping team will help you solve problems from design to manufacturing. We help everyone with our rapid manufacturing services, from established design teams to entrepreneurs with bold ideas. We help our customers realize the potential of their designs and ensure the successful launch of their products.

Rapid Prototype Manufacturing Capabilities

Are you looking for professional prototyping services to help realize your ideas and assist in product development? Xtmade has cutting-edge prototyping and production manufacturing technology, advanced industrial-grade equipment, and a team of professional engineers to take your ideas from design to market in just a few days. We can provide high-quality, fast-turnaround, and cost-effective rapid prototyping services to customers around the world. Below are the main types of rapid prototyping services we provide.

3D Printing

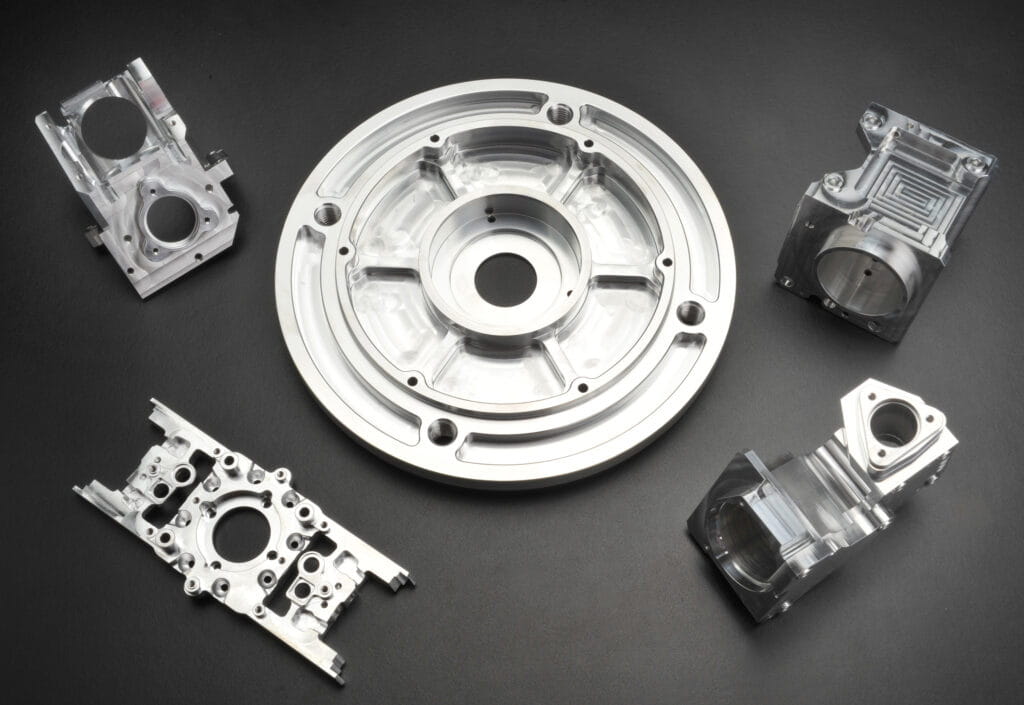

CNC Machining

Injection Molding

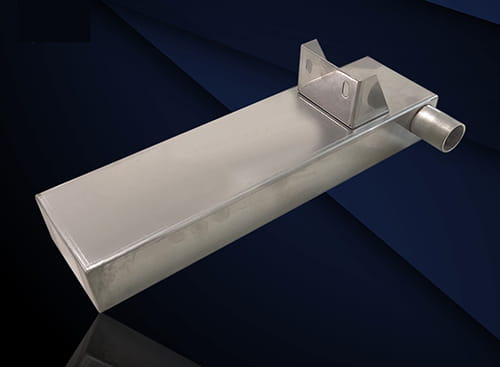

Sheet Metal Fabrication

Better design

Quickly perfect your part designs with our rapid manufacturing capabilities

Are you looking for ways to accelerate your new product development process? Is it challenging to find a manufacturing partner that can provide not only equipment, but also design and engineering expertise to help you get your ideas to market faster? Xtmade can help you quickly iterate on part designs and accelerate new product development.

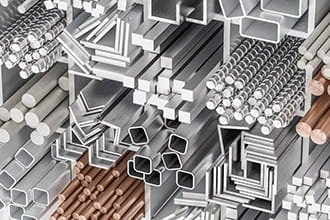

Materials

Our rapid prototyping services are able to handle a wide range of materials and can bring your entire rapid prototyping project together in one place. We can manufacture your prototype parts in plastics, metals, and ceramics.

Plastics

Metals

Ceramics

Types of Rapid Prototyping Applications

Rapid prototyping covers different techniques and materials. Depending on the application, there are many types of prototypes.

Concept Model

A proof-of-concept prototype is the simplest prototype and is used to communicate the basic design of a part. It is mainly used for internal iteration of products.

Display Prototype

A demonstration prototype (or cosmetic prototype) is a model that focuses on appearance. It should be as similar as possible to the final part, but it may not function as designed.

Functional Prototype

Functional prototypes function similarly to the end-use part. This allows the designer to perform any necessary mechanical testing on the prototype to ensure it functions properly.

Pre-production Prototype

A pre-production prototype or factory sample is a prototype made before production. It is mainly used to validate the selected mass production process and ensure that the manufactured part will function as expected.

What is rapid prototyping?

Rapid prototyping is the process of turning a product idea into a physical model using various production technologies. A product project is basically an idea in the early stages, and if you want to sell the product or get investors interested, you need a physical model, also known as a product prototype.

To bring a product to market, you need to improve it until you get a final version that can be put on the market. Therefore, the faster you can make and improve prototypes, the faster you can bring your product to market. Currently, all rapid prototyping work starts with a digital model, but the manufacturing hardware can include CNC machining, 3D printing, etc. You can make rapid prototypes using any material that is compatible with the manufacturing hardware you use. This may or may not include surface treatment. Therefore, when you want to develop and deliver a product using rapid prototyping services, the faster the better.

Prototyping Benefits

- Cost-effective approach

- Reduces material waste

- No special tooling required to make models

- Flexibility to perform multiple design iterations in color, surface texture, design, and finishing

- Early physical verification of designs helps reduce overall risk

How to Choose the Right Rapid Prototyping Technology

The right prototyping method is the one that fits your budget, the complexity of your part, the functions you want the prototype to perform, and your development timeline. Better prototypes cost more money and take longer to make, but they also better address issues such as form, fit, and function of production parts. Therefore, you need to answer the following questions to get the right rapid prototype parts.

- Is the prototype a static display model?

- Does it need to be fully functional?

- Are there multiple interrelated parts?

- What is the surface texture and finish?

- What is it made of?

- How important are strength and durability?

- How close should it be to the final production version?

Industries We Serve

We specialize in providing additive manufacturing services to a wide range of industries around the world and are committed to providing excellent service and product quality. Below are some of the industries we serve.

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Start Your Project With A Free Quote

We have a range of integrated development solutions and our rapid prototyping services enable you to evaluate your product with less risk.

Latest News

Xtmade team summarizes technical issues related to CNC machining

The CNC machining industry needs to solve problems…