Additive Manufacturing (AM)

Metal 3D Printing Service

Your online metal 3D printing service. Upload your 3D model, choose from a variety of different finishes and materials, select the print size, receive an instant quote, and let us take care of printing and shipping your product.

Your Metal 3D Printing Service Provider

Elevate your metal part manufacturing projects with Xtmades metal 3D printing services. Premium metal 3D printing services can transform concepts into achievable metal art. Our state-of-the-art technology, coupled with the expertise of our team of skilled engineers, ensures your project is built with unparalleled precision and quality. From complex designs to strong end-use parts, our 3D metal printing capabilities cater to a wide range of industry needs. As a professional metal 3D printing service provider, we pride ourselves on creating results that exceed expectations. Working with us, you get more than just service, you get a combination of innovation and craftsmanship, exploring the future of metal manufacturing with our metal 3D printing facility in Shenzhen, China. We can customize parts to your exact specifications with a wide range of materials and finishes for you to choose from. Contact our team of engineers for pricing and delivery times so we can get started on your project as soon as possible.

Our Metal 3D Printing Solutions

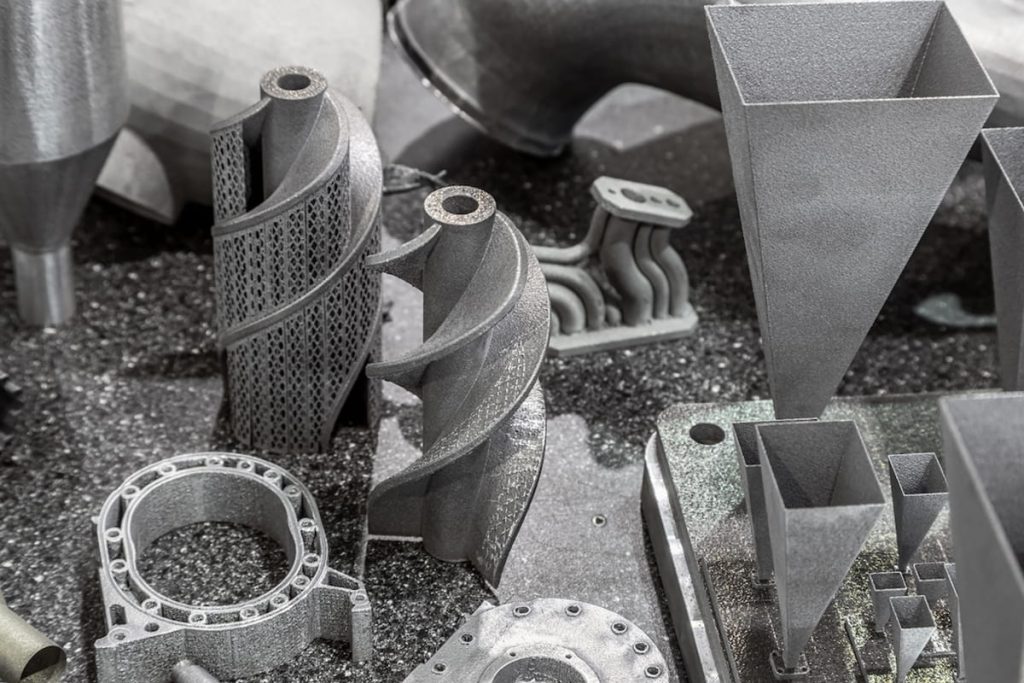

Xtmade provides metal 3D printing services covering the entire workflow, from project consulting, part design and engineering, research and development to prototyping and serial production manufacturing services. Our metal 3D printing services ensure improved functional performance, better mechanical properties, special structures and complex geometries to technically meet the overall requirements of the component. We can also provide customized part solutions based on the requirements of your industry. Value delivery and business results are at the core of our solutions and services, and are supported by our strong quality management system.

Metal 3D printing types

Metal 3D printing produces strong and durable parts. They can be printed using high-strength, lightweight materials with high tensile strength, hardness, and wear resistance. Here are the types of metal material 3D printing processes Xtmade offers.

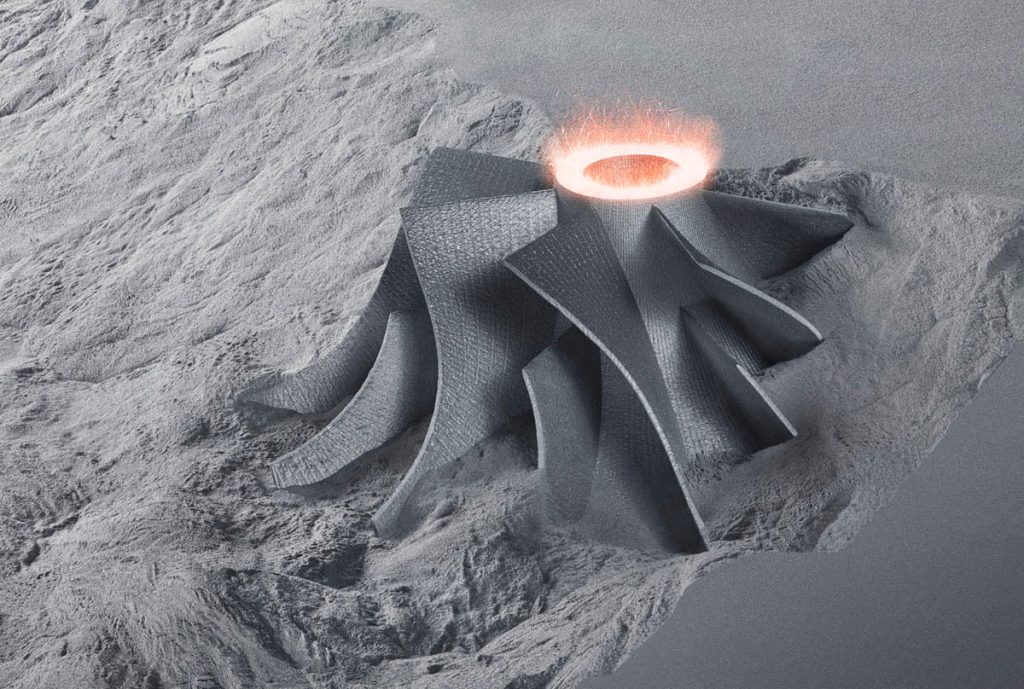

Selective Laser Melting (SLM)

Electron Beam Melting (EBM)

Laser Deposition Welding(LMD)

Metal Powder Application(MPA)

Direct Metal Laser Sintering (DMLS)

Metal Binder Jetting

Thinking about metal part design

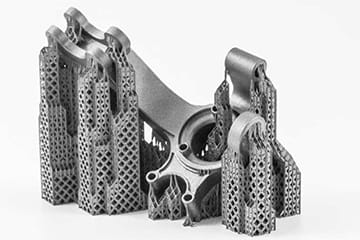

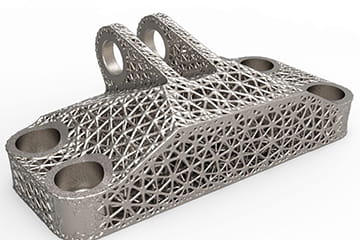

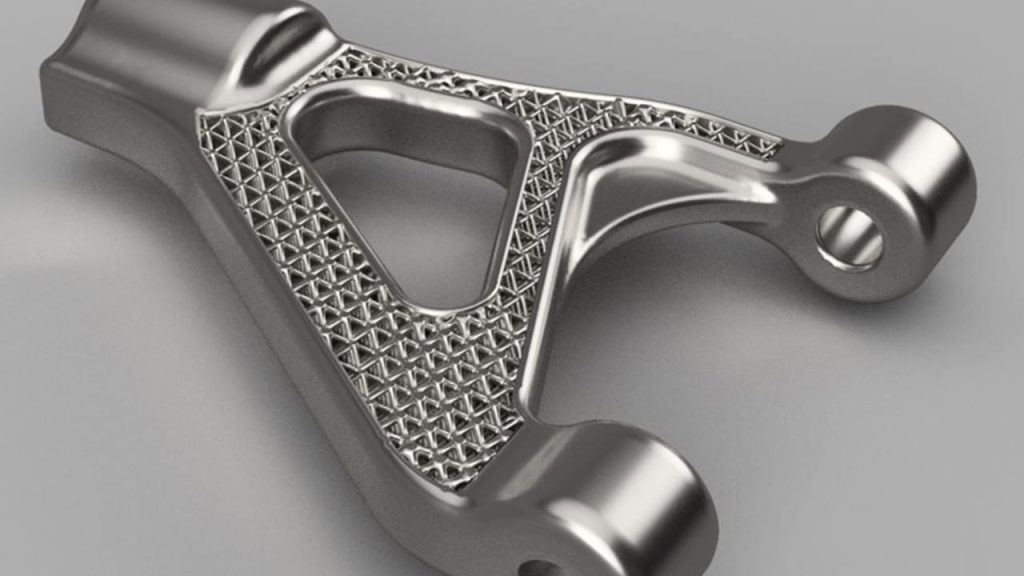

Subtractive manufacturing technology limits what you can create. Metal 3D printing enables you to produce part designs that are difficult or impossible to achieve with traditional manufacturing technology. For example, the following design points cannot be produced by subtractive manufacturing technology.

- Internal supports

- Weight-saving lattice wall sections

- Conformal cooling channels

- Undercuts

- Draft angles

- Internal cavities

- Varying wall thicknesses

Materials

- Titanium

- Steel

- Stainless steel

- Aluminum

- Nickel

- Cobalt

- Copper

- Inconel

- Gold

- Platinum

- Silver

Surface finishing

- Abrasive Blast (Grit & Ceramic)

- Shot Peen

- Optical Polish

- Electrochemical Polishing

- Abrasive Flow Machining

- Electroplating

- Micro Machining Process (MMP)

What is Metal 3D Printing?

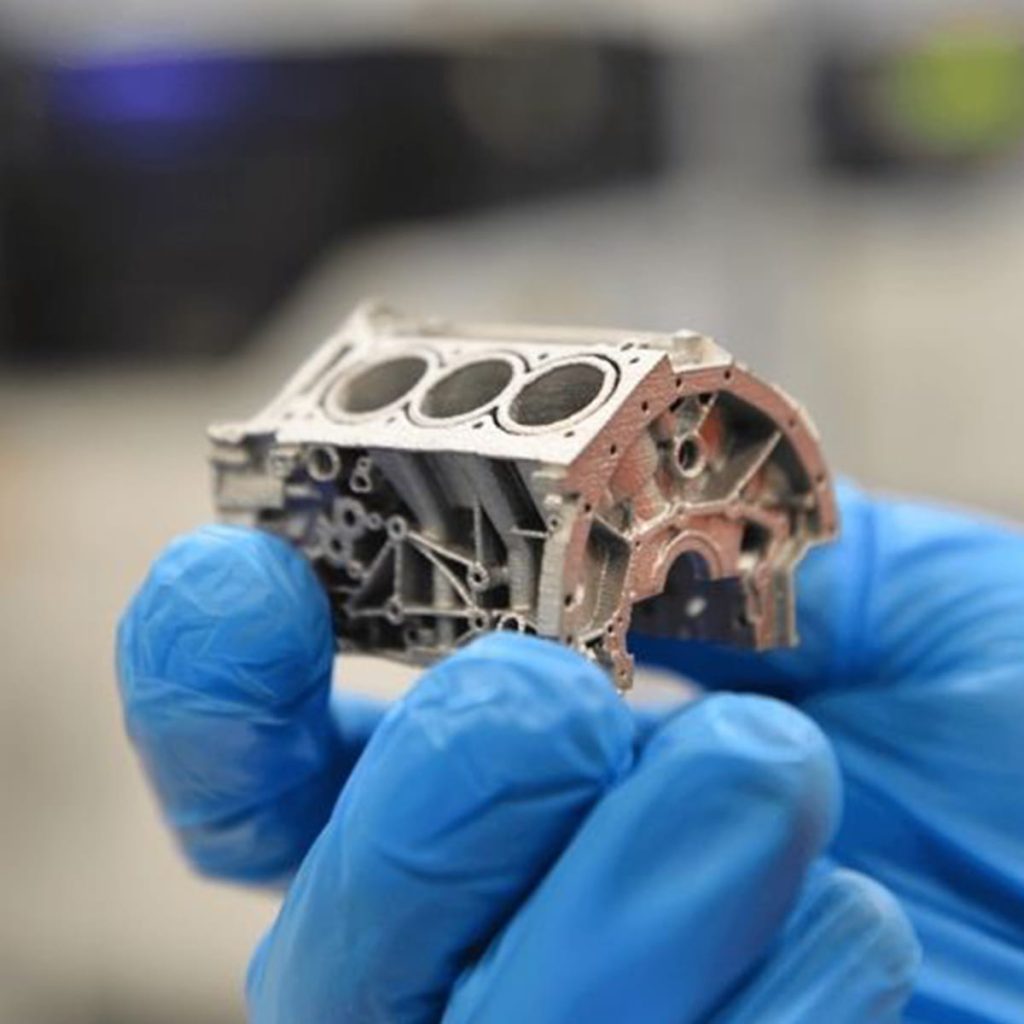

Metal 3D printing is an additive manufacturing process that produces parts by fusing metal particles together layer by layer to form a metal component. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedom that 3D printing offers. It can produce complex designs and structures, neither of which can be manufactured through traditional CNC machining.

Applications of Metal 3D Printing

Metal 3D printing can be used for rapid industrial tooling as well as parts with complex curvatures and small thin-walled parts such as conformal jigs and fixtures, stamps, dies, and cutting inserts. In addition, metal 3D printing can be used to integrate fastening features, end effectors, and metal lattice structures. Due to the excellent durability and strength of metal 3D printed parts, they can be used for fully functional late-stage prototypes or end-use parts for any of the above applications.

- Functional Prototypes

- Direct Digital Manufacturing

- Molds and Inserts

- Piping Systems

- Rapid Tooling

- Spare Parts

- Rigid Housings

- Radiators and Heat Exchangers

Advantages of Metal 3D Printing

- Can produce parts with unique geometries, and can make parts that cannot be made by other means. For example: internal cavities and other complex features that cannot be machined or cast.

- Design freedom, can combine parts into a lighter, cheaper, more reliable printable part.

- Ideal for rapid prototyping, can quickly iterate prototype part designs, and can also use it to print multiple design ideas of the part at the same time to determine which is the best functional design.

- No fixtures or tools are required to produce metal parts. And part designs can be easily modified or fine-tuned during the production process.

- For mass production of customized parts, metal 3D printing services can quickly produce hundreds of production-quality parts to keep the production line running when bridge production is needed.

- Metal 3D printed parts have excellent toughness and can produce jigs and fixtures for CNC machining, part inspection and other purposes.

Industries We Serve

Xtmade provides professional metal 3D printing (additive manufacturing) solutions to help engineers, designers and manufacturers in aerospace, defense, medical, robotics and other fields push the boundaries of design and production.

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Ready to start your project?

Contact our 3D metal printing experts today! Our team is ready to answer your questions or provide a quote for your project.