A complete guide to the rubber insert molding process

A complete guide to the rubber insert molding…

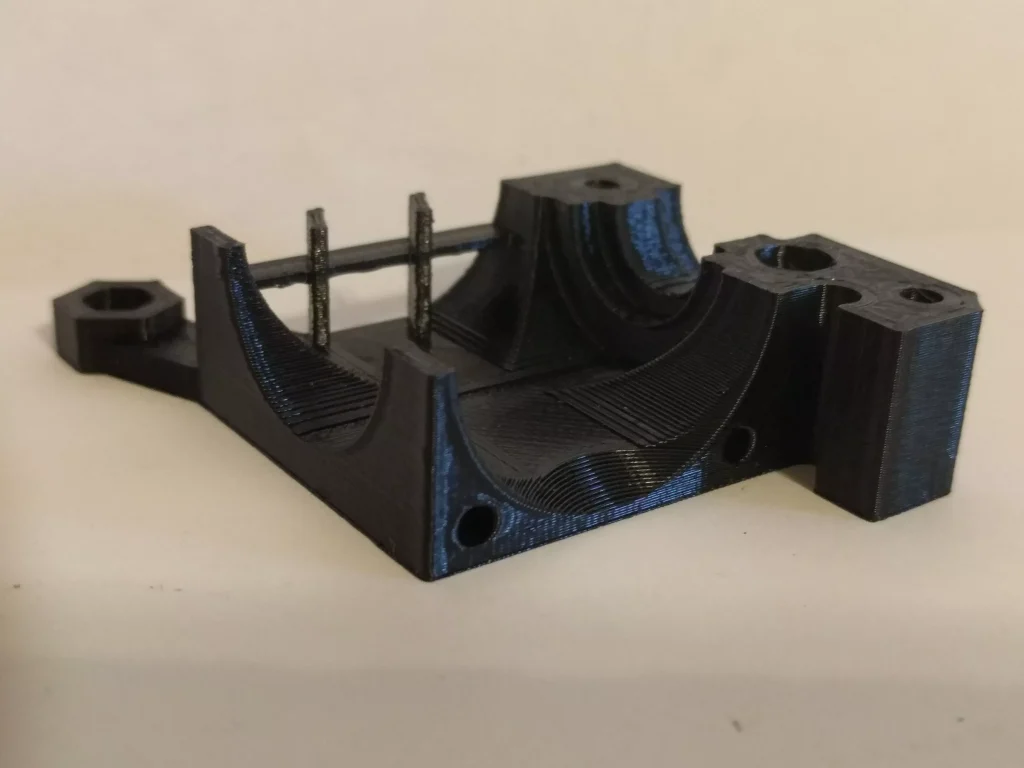

3D printing is an extremely fast, efficient, and cost-effective way to produce parts. We have the capacity to print in both large and small batches, to help you refine your prototypes and then get started production-size runs.

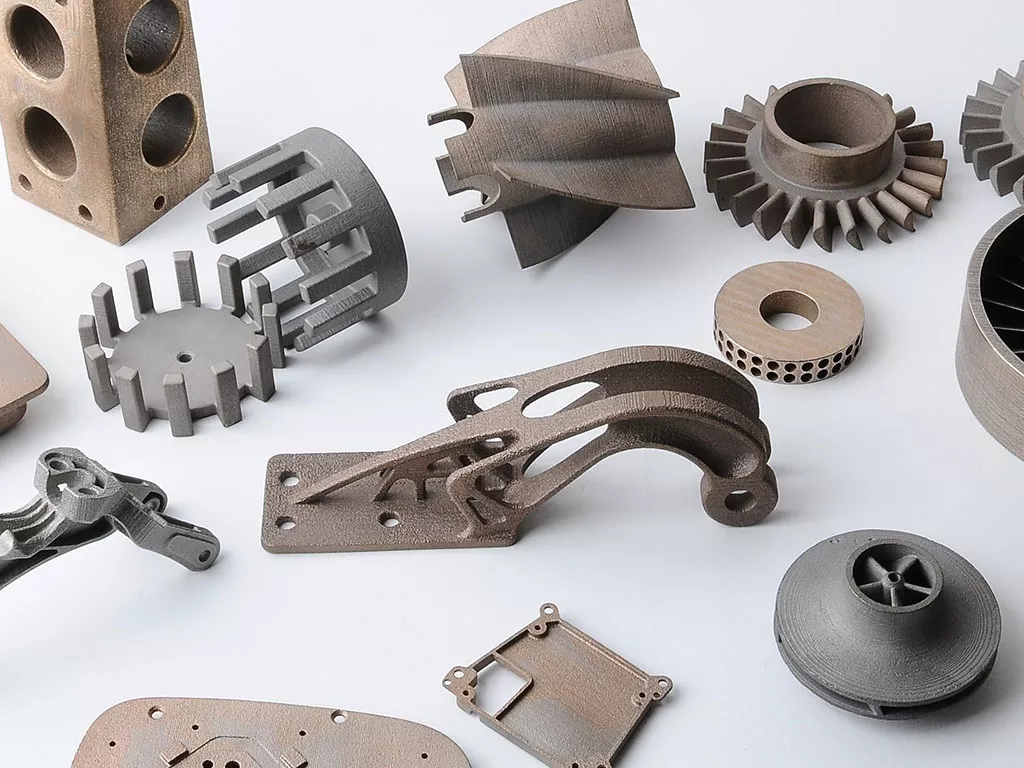

Our online 3D printing service enables you to 3D print custom parts on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With over 120 3D printers, we have unmatched capacity to reliably deliver parts in days. In addition to a broad material selection, we offer a variety of post-processing options to improve appearance or enhance mechanical properties. With more than a decade of pioneering experience, we offer the industry's most comprehensive selection of metal and plastic 3D printing technologies and materials for any application, whether small or large, simple or complex, prototype or production. Our experts work closely with your team on everything from identifying and evaluating 3D printing candidates to exploring design improvements and cost savings.

From intricately designed prototypes to robust final production components, we stand as the solution's premier destination for top-notch 3D printed outcomes.

| Description | Tolerance Notes |

|---|---|

Part Size | XTmade can accommodate 3D printing up to 24″ x 36″ x 36″ without the need to split and bond parts. |

Minimum Feature Size | 0.030″ – 0.060″ is typical. |

Minimum Wall Thickness | 0.020″ – 0.060″ is typical. |

Clearance Between Features | At least 0.030″ |

Trusted by industry leaders, XTmade doesn’t just manufacture custom parts, we create tailor-made solutions to elevate your project. When you work with us, you’ll get on-demand 3D printing, customized workflows to best fit the needs of your manufactured parts, advanced verification and validation capabilities such as First Article Inspection (FAI) or Production Part Approval Process (PPAP), and three state-of-the-art additive ecosystem facilities.

Our suite of secondary and finishing services ensures your parts not only meet but exceed your exact specifications. From design to delivery, XTmade is an advanced 3D printing service that expands the possibilities of additive manufacturing, providing customers with precision, reliability, and unmatched quality. Choose us for a seamless journey from concept to creation.

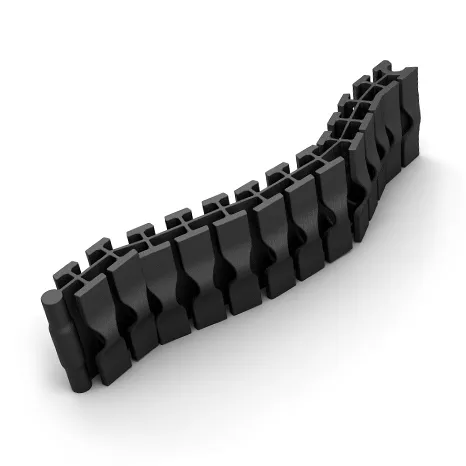

3D Printing is an additive manufacturing process used for rapid prototyping, producing custom built parts, and low volume production runs. As the best option for a quick lead time at an affordable price or when the part geometry does not allow the use of traditional manufacturing methods and technologies, 3D Printing is a diversely adaptive manufacturing process. Rapid prototypes, mechanical parts, tools, cosplay costumes, game pieces, and jewelry can all be built using various 3D Printing methods.

Building parts layer-by-layer brings about many benefits that open up design possibilities that were previously unachievable through traditional processes like injection molding, cnc machining, or casting.

With a wide variety of 3D printing materials available, it is important to ensure that you pick the correct one for your project.

SLS

MJF

PA 12

PA 11

Glass filled PA 12

Full Color PA 12

SLA

SLM

Metal

plastic

XTmade’s 3D printing services offer a variety of flame retardant polymers that meet UL-94 V-0 and FAR 25.853 60-second burn test standards. These include FDM ULTEM 9085, FDM ULTEM 1010, and SLS Nylon 12 flame retardant. These polymers are ideal for aerospace applications. Learn more about 3D printing flame retardant plastics.

From intricately designed prototypes to robust final production components, we stand as the solu XTmade has various tools and machines to remove support material from 3D printed parts. We use soluble support material, allowing the creation of complex geometries.

We can also handle light 3D printing post processing in the line of sanding, polishing, clear-coating, marine epoxy coating (for waterproofing FDM), and adding heat set inserts. For large printed parts or more specific post processing techniques, we work directly with a local shop to handle your needs.tion's premier destination for top-notch 3D printed outcomes.

Additive manufacturing can be leveraged for both rapid prototyping and production in aerospace, medical, automotive, and other large industry sectors.

Upload your 3D CAD file to get an instant quote for your 3D printed design. In our quote platform, you can see real-time cost impacts based on your selected 3D printing material and resolution level.

If you have any questions about quotes or designs, you can work with our application engineering team who will help you through the process.

A complete guide to the rubber insert molding…

A guide to on-demand manufacturing for low-volume injection…

Understanding the Design and Application of ABS Plastic…

Don’t miss our future updates! Get Subscribed Today!