A complete guide to the rubber insert molding process

A complete guide to the rubber insert molding…

Custom injection molding is ideal for plastic parts where success relies on achieving specific mechanical or aesthetic features.

With a one-stop facility, XTmade has been a leading manufacturer of high-tonnage custom and large-part injection molding. We want to provide a single, convenient source for your injection molding needs. With our diverse selection of plastic injection molding equipment, our company can meet all of your plastic injection molding needs. We have mastered developing a complete plastic manufacturing strategy, and our goal is to go far beyond manufacturing plastics.

XTmade proudly offers best-in-class full-service project management, convenient assembly, product distribution, and logistics to streamline your manufacturing process and help you keep your company up and running. Our comprehensive plastic injection molding services help our customers save money, reduce overhead, shorten time to market, and improve overall product quality. That’s why we are the injection mold manufacturer of choice for businesses across the United States.

We are pleased to have the necessary tools to meet the needs of businesses of all sizes in a variety of industries. Our mission has always been to help our customers produce as many quality products as possible to meet their needs, regardless of shape or size. Learn more about why UPM is a leader in plastic mold manufacturing and how you and your business can take advantage of our services.

XTmade prides ourselves and our custom plastic injection molding services on working with companies to develop robust processes using Scientific Molding methods, making your ideas come to reality. Molding both medical and non-medical devices, we can incorporate any of the following into your designs:

XTmade offers common metals for injection molding tooling, and a variety of popular plastic materials.

Hard Plastics

Mixed plastic

Rubber-Like Varieties

Flexible Plastics

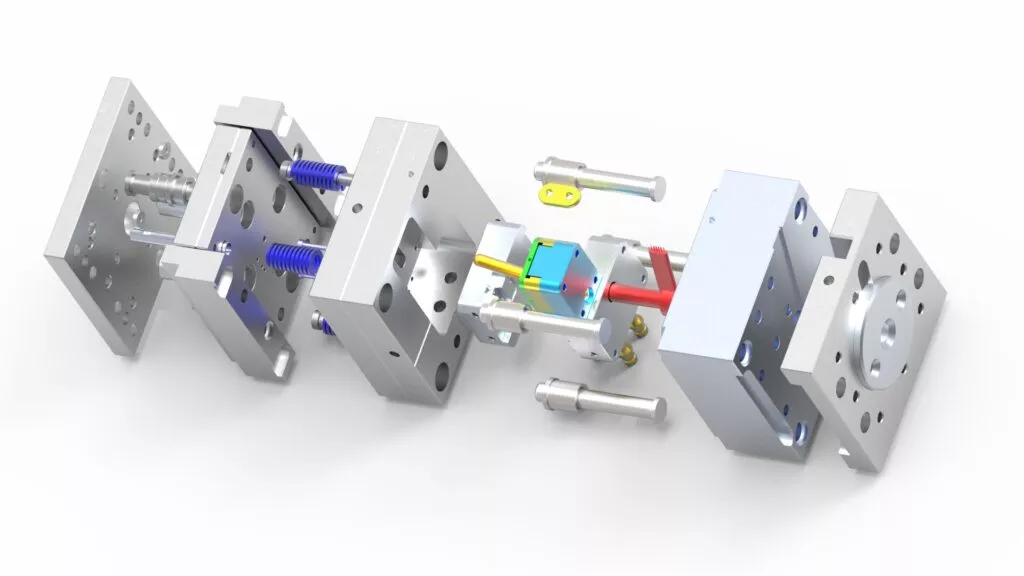

Molding is a manufacturing process that involves shaping a liquid or malleable raw material by using a fixed frame, known as either a mold or a matrix. The mold is a hollow cavity receptacle, commonly made of metal, to pour liquid plastic, metal, ceramic, or glass material. In most cases, manufacturers derived the mold from the initial pattern or template of the final object; its main objective is to reproduce multiple uniform copies of the final product. The liquid must cool and harden inside the mold to achieve the final configuration. Injection molding services generally use a release agent or ejections pins to remove the mold.

The sequence of events during the injection mould of a plastic part is called the injection molding cycle. The key steps in the injection molding cycle are:

Clamping: The two sides of the mold are closed and clamped shut.

Injection: The material is fed into the machine and pushed towards the mold. While this is happening, the material is melted by heat and pressure. The plastic is then injected into the mold — this is called the “shot.”

Cooling: The plastic in the mold cools and solidifies into the shape of the part.

Ejection: After the part cools, it is ejected from the mold.

Up to now, we have completed 7000+ projects, including Automotive interior and exterior accessories, Medical device parts, Electronic plastic components, Smart household parts, Security parts and so on.

We offer high standard injection molding services, support low volume manufacturing, fast delivery, and quick respond within 24 hours.

A complete guide to the rubber insert molding…

A guide to on-demand manufacturing for low-volume injection…

Understanding the Design and Application of ABS Plastic…

Don’t miss our future updates! Get Subscribed Today!