A complete guide to the rubber insert molding process

A complete guide to the rubber insert molding…

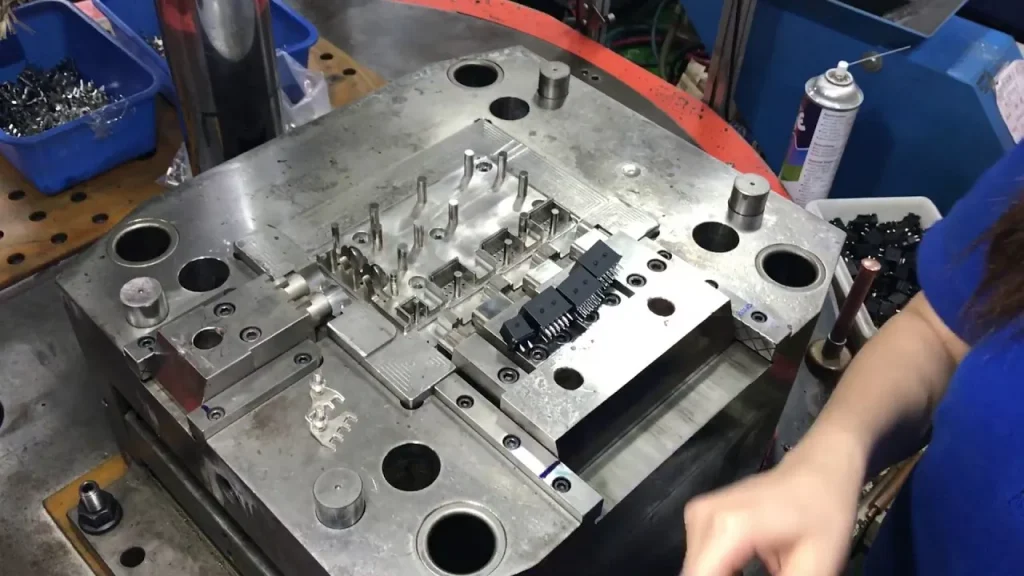

Insert Molding is the manufacturing process of overmolding a preformed part (typically metal) with a heated thermoplastic resin to produce a single unit. Molding inserts can be simple items such as rods, thread, or a knife blade, but they can also be complex.

We are an ISO certified business providing engineering, custom injection molding and contract manufacturing services. Our customers bring demanding applications that require insert molding services and expert engineers provide the best service.

All of our injection molding machines are equipped with servo-driven robots for high-speed automation and production of insert molding services. Our engineers’ experience includes mold qualification for medical IQ/OQ/PQ, high-volume automation for consumer packaging, and engineering grade resins and ultra-polymers in electronics.

We have developed hundreds of products, some of which offer insert molding services, and manufacture millions of parts per year for the medical industry. Medical devices include point-of-care diagnostics, microfluidics, and drug delivery applications.

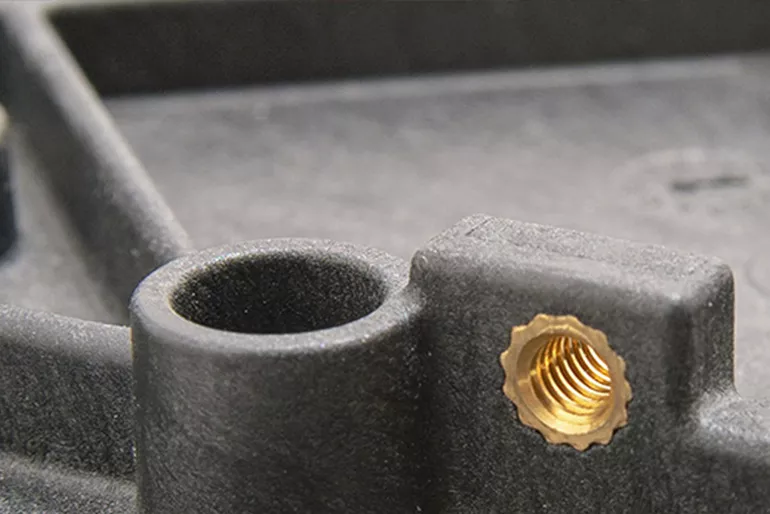

Insert Molding is an injection molding process that works especially well for parts that have threaded holes. It can also help you create better wheels, pulleys, fan blades, and other similar parts. Done correctly, insert molding can help:

There are many substrates used in insert molding, but the most popular is brass threaded inserts and bushing. In addition, many companies make custom inserts that can be insert molded. It is really left up to the imagination when deciding what type of inserts can be over molded.

The benefit to insert molding is that parts can be mass produced faster than machining whole parts out of metal. Even though insert molding adds to the cycle time (typically 15 seconds per insert) it is still much faster than cnc machining a part from a solid block. Furthermore, by insert molding metals where necessary and replacing the rest of the part with plastic will in turn reduce the overall weight of the part.

Did you know you can insert mold plastic parts? This process is called over molding and it lends itself when you need two or more different materials in the same part.

Here are the most commonly used materials for plastic injection molding:

Engineering and general purpose plastics are being used in our Injection Moulding section to produce a wide range of parts from audio-video, hi-fi and multimedia speakers, telecommunications, consumer product, precision parts for I.T. hardware, engineering hardware, specialized equipment, fax machines, scanners and scales. Well-maintained machines ranging from 20 to 800 tons, totaling 52 units supported by ancillary equipment such as robotic sprue pickers, heat & cool temperature controllers, chillers, dehumidifiers, dryers and autoloader are being manned by skilled, well-trained staff and technical team and processes are subjected to stringent inspection to ensure conformity to our customers’ requirements.

Receive Your Same-Day Quote and Risk-Free Project Evaluation

A complete guide to the rubber insert molding…

A guide to on-demand manufacturing for low-volume injection…

Understanding the Design and Application of ABS Plastic…

Don’t miss our future updates! Get Subscribed Today!