Aerospace

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Get products to market faster, reduce risk, and streamline production with on-demand production at competitive prices. Contact us today for an instant quote.

Reduce Risk, Launch Faster and Accelerate Innovation

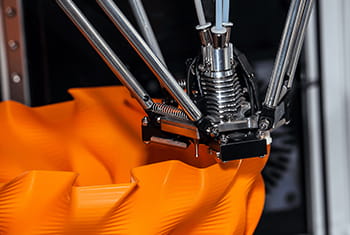

Design and manufacturing at different stages of the aerospace industry require a habit of development and striving for perfection. Every step of the project involves high risk, so high-quality manufacturing partners and suppliers are needed from the beginning. At Xtmade, we understand the need for excellence in aerospace product manufacturing. That’s why we strive to manufacture your parts at every stage, from material testing to serial production. Our batch-independent rapid prototyping and on-demand production services are ideal for high-precision parts that can be manufactured and delivered to you to specification. Our engineers can work with you through our CNC machining services, sheet metal fabrication, and 3D printing services to accelerate your product development cycle, reduce risk, and help validate designs.

On-demand rapid manufacturing

Our reliable custom parts service has served numerous clients representing different stages of the aerospace industry. As a result, we have adapted our internal production system to ensure that any order, no matter how big or small, is produced on time and delivered to every customer. Our production system can produce parts in small or large batches, and most importantly, our quality standards remain relatively high. The product design phase in our company is shortened because we only use the right tools that can quickly capture all relevant product details. We can quickly create aerospace part prototypes and show them to our customers, who can then decide if certain changes must be made to the original design.

Why choose US

Xtmade specializes in reliable aerospace component prototyping and production, with projects ranging from simple to complex. We combine manufacturing expertise with advanced technology and strict adherence to quality requirements to turn your ideas into reality. Whatever the end use of your aircraft parts, Xtmade can help you achieve your unique goals.

Strong production capacity

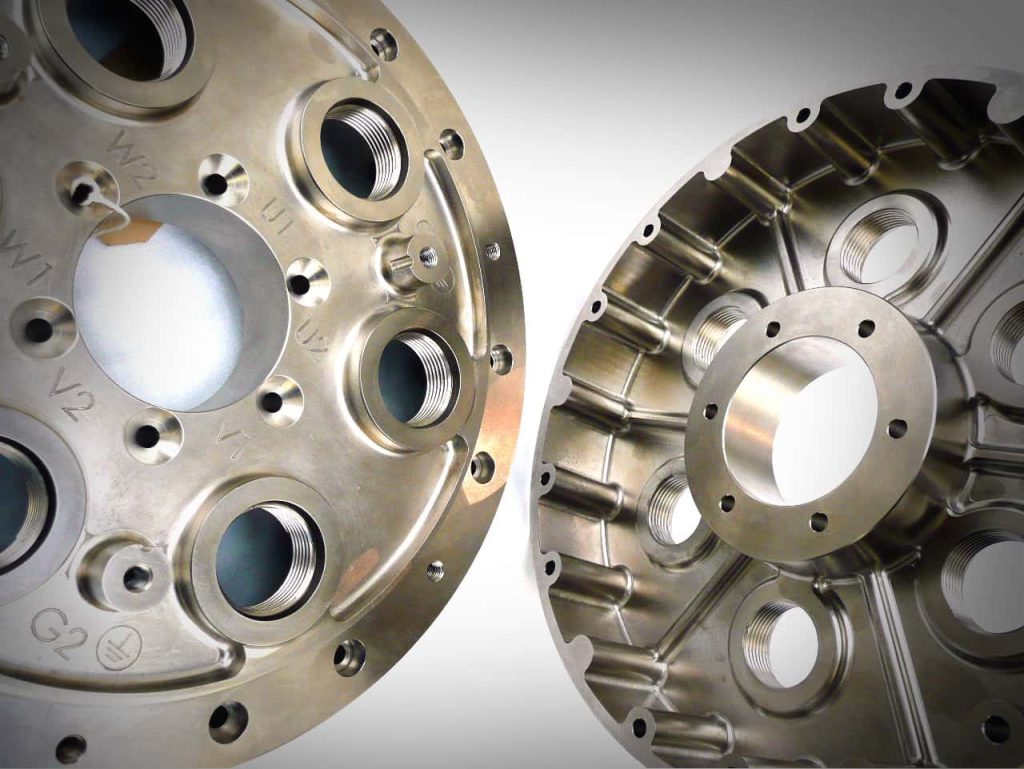

Xtmade’s production line uses advanced technology to ensure manufacturing accuracy and precision. Each aviation part has the correct size specifications, structural strength and performance.

Tight Tolerance Aerospace Parts

We can machine aerospace parts with tolerances up to +/- 0.001″. Our tolerances for metals are ISO 2768-m and our tolerances for plastics are ISO-2768-c. Our manufacturing capabilities can also accommodate complex custom part manufacturing designs.

Fast Cycle Time

Get a quote in 4 hours, with Xtmade you can reduce your cycle time by up to 50%. The perfect combination of advanced technology and rich technical experience helps us provide quality aerospace parts with faster delivery time.

Aerospace Manufacturing Capabilities

You can benefit from our professional manufacturing services throughout the entire production cycle, from prototyping and design verification to functional testing and product release. We provide high-quality, precision combat parts with fast turnaround times and low costs. With our quality control process, you can be sure to get parts that meet your unique requirements.

All-in-one Solution for Aerospace lndustry

Which materials are suitable for manufacturing aerospace components?

- Titanium: Available through machining and metal 3D printing services, this lightweight and strong material offers excellent corrosion and high temperature resistance.

- Aluminum: This metal’s high strength-to-weight ratio makes it ideal for housings and brackets that must withstand high loads. We offer 7075 T7 aluminum, which can handle the repetitive stress cycles typical of aerospace components, and 2024 T3 aluminum, which offers high corrosion resistance, which is critical for components exposed to harsh environments.

- Inconel: This 3D printing metal is a nickel-chromium super alloy that is ideal for rocket engine components and other applications that require high temperature resistance.

- Stainless Steel: SS17-4 PH is widely used in the aerospace industry for its high strength, good corrosion resistance, and good mechanical properties at temperatures up to 600’F. Like titanium, it can be machined or 3D printed.

- Liquid Silicone Rubber: Our elastic fluorosilicone materials are specifically targeted for fuel and oil resistance, while our optical silicone rubber is a good alternative to PC/PMMA.

Perfect your parts with our finishing options

Our finishing services can further enhance the range of production technologies we offer to the aerospace industry. We understand the need for superior part quality and appearance. That is why we offer many finishing options to enhance the surface finish of your parts. Our finishing is decorative, aesthetic, and in some cases functional. See below for a list of the finishing options we offer for your aircraft components and aerospace parts:

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

Aerospace Applications

Our manufacturing capabilities help speed production of a wide variety of aerospace components to meet unique application needs. Here are some other common aerospace applications.

- Rapid Tooling, Brackets, Chassis, and Fixtures

- Turbine Pumps and Manifolds

- Heat Exchangers

- Mating Check Gauges

- Custom Fixtures

- Fuel Nozzles

- Conformal Cooling Passages

- Gas and Liquid Flow Components

Intellectual Property Protection

The security of intellectual property and technology is an aspect that cannot be ignored, so it involves sharing ideas and sensitive information with partners who attach great importance to confidentiality agreements. In industrial applications in the aerospace field, signing a confidentiality agreement is a common means to protect the interests of customers, and Xtmade will sign an agreement to promise not to disclose confidential information of customer products without the customer’s permission. When you seek our help on any matter we handle, you will find that you have made the right choice.

Ready to get started? We make it easy!

Ready to start your next project? Working with us will help you accelerate the manufacturing of aerospace prototypes and parts. Our expert engineers will send you recommendations on how to optimize your design for cost-effectiveness and ease of purchase.

Latest News

Xtmade team summarizes technical issues related to CNC machining

The CNC machining industry needs to solve problems…