Automotive

On-demand manufacturing for the automotive industry, overcoming the ever-shortening development cycles of conventional, electric and autonomous vehicles through rapid prototyping and low-volume production. Get an instant quote now.

Accelerating Automotive Product Development with On-Demand Manufacturing

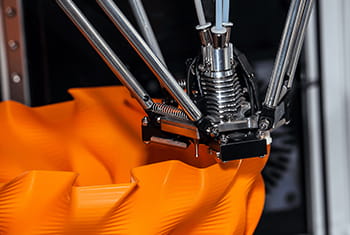

The automotive industry is evolving at a high speed. As industry trends such as driving, in-vehicle connectivity, and hybrid/electric vehicles continue to drive innovation, agility-focused automotive companies are turning to accelerate new product development and bring products to market faster. With rapid digital manufacturing and automated manufacturability feedback, engineers can reduce design and cost risks while developing a more responsive supply chain to better respond to driver and passenger demands for more custom vehicles. Xtmade works with a variety of automotive and component companies to streamline their supply chains and dynamically scale their manufacturing capabilities. Think of it as a production capacity service. Leading electric vehicle companies and autonomous driving startups are also working with Xtmade to build the infinitely scalable on-demand supply chain of the future to bring products to market faster. We have expertise in injection molding, CNC machining, sheet metal fabrication, and 3D printing for the automotive industry. We also work with other types of automotive manufacturers, such as motorcycles.

Why does the automotive industry need prototyping?

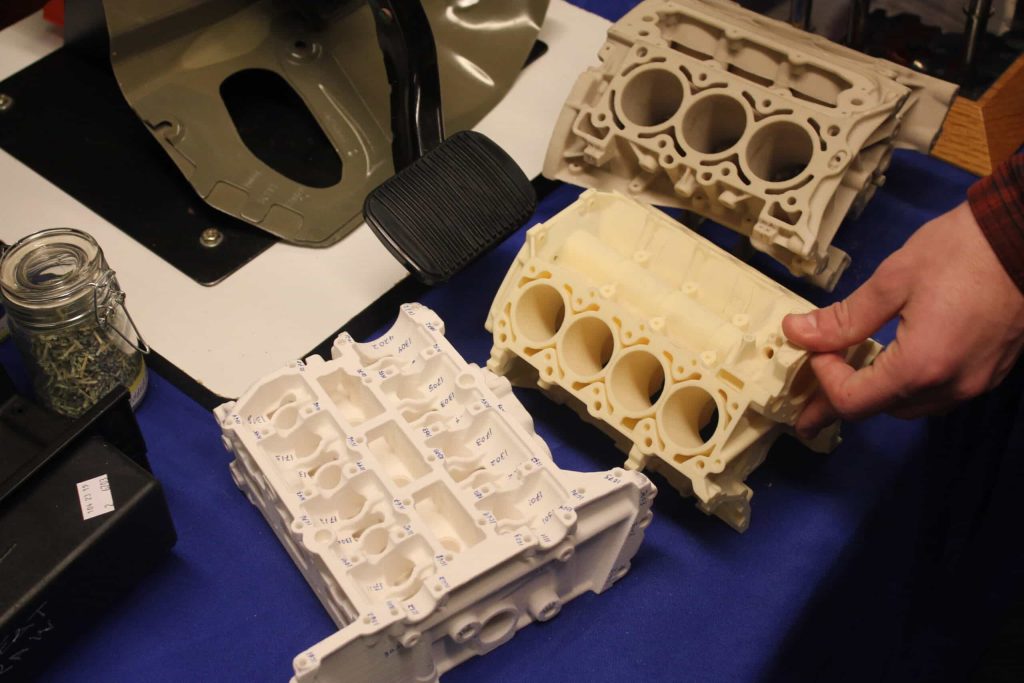

The automotive industry is a complex and large industry that faces market pressures and requires frequent design iterations and new design development. However, the automotive design and development cycle is a long process, so efficient prototyping is an indispensable bridge. Automotive prototyping is an important step in the verification process between initial product design and final production run. The prototyping process will help the design team figure out how to make the new design appeal to consumers and prove its value, how to communicate ideas and iterate designs with stakeholders and project teams faster and more effectively, and how to verify and test functions and evaluate the part manufacturing process.

Automotive Prototyping and Manufacturing with Xtmade

The prototyping process will help design teams figure out how to make new designs appeal to consumers and prove their value, how to communicate ideas and iterate designs with stakeholders and project teams faster and more effectively, and how to verify and test functionality and evaluate part manufacturing processes.

At Xtmade, we provide rapid prototyping and CNC machining, 3D printing and other services to automotive industry customers. Our team of experts has the knowledge and skills to help turn new product concepts into reality. To learn more about our prototyping capabilities and how we can serve the automotive industry, please contact us or request a quote today.

From design to production and everything in between

No matter what type of automotive manufacturing services you need, whether it is automotive seat parts manufacturing, automotive components, rapid prototyping or contract manufacturing, we are a one-stop solution provider at every stage – from concept to production. We complete the work on time and with excellent quality. Our passion for innovation drives and manufactures high-quality automotive parts and accessories, constantly raising the bar for consistency, safety and performance.

Automotive Manufacturing Capabilities

Xtmade offers a wide range of manufacturing processes for automotive prototypes and production parts. We provide top quality services at different stages of the production cycle, from prototyping to mass production.

Ready to get started? We make it easy!

We are experienced in automotive prototyping and automotive parts manufacturing and look forward to providing you with a better experience. With Xtmade, you will find a process that meets your needs and fits your product definition.

Why choose US

By partnering with us, automakers gain multiple benefits that boost their business and increase their profit margins.

Competitive Prices

Thanks to our cost controls and streamlined production, you can guarantee 30% lower costs and low minimum order quantities for automotive parts, prototypes, and products.

Streamlined Production

Xtmade has well-equipped factories and a mature supply chain, ensuring a stable supply of auto parts during peak periods.

Fast Cycle

Through our team’s capabilities, we can quickly transform your automotive component designs into real, viable products that fit your business.

Professional Support

We can work with the automotive manufacturing industry and business, our engineers have full capabilities and requirements.

Which materials are suitable for automotive applications?

All of our manufacturing processes offer a wide range of material options. Listed below are some common choices for automotive projects.

- Steel

- Aluminum

- Titanium

- PA(Nylon)

- PMMA

- Silicone

Automotive Parts Post-Processing Capabilities

- Anodizing

- Passivization

- Electroplating

- Powder Coating

- Insert Installation

- Heat Treatment

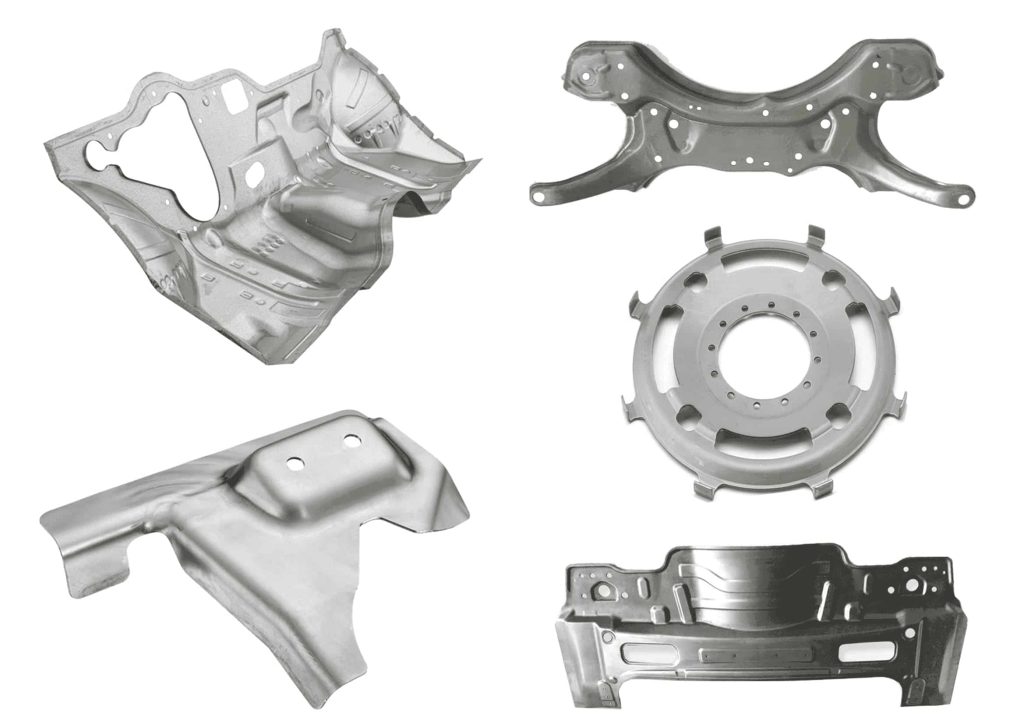

What kind of automotive parts can we make?

Here are some of the types of auto parts we can manufacture for you.

- Prototypes

- Replacement parts

- Legacy/obsolete parts

- Electric vehicle and battery parts

- Jigs and fixtures

- Support for vehicular consumer electronics

- Plastic dash components

- E-bike and scooter parts

- Custom body parts

- Commercial/utility vehicle parts

- Dashboard and steering wheel components

- Housing and enclosures

- Armatures

- Assembly line components

- Lighting and lenses

- Bumpers

- Engine parts

- Lighting features and lenses

- Aftermarket parts

- Fixtures

Start a new project today

Electric and self-driving cars are among the hottest growth areas today. More than ever, automotive companies are transforming and need specialized parts to keep up with the demand. Are you ready?

Latest News

Xtmade team summarizes technical issues related to CNC machining

The CNC machining industry needs to solve problems…