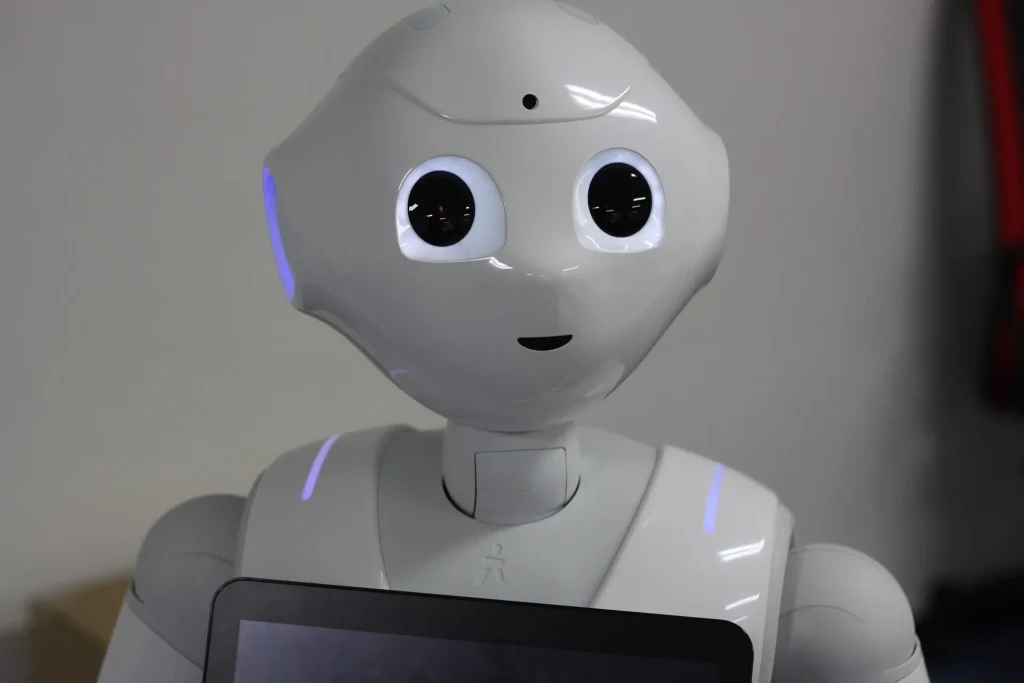

Robotics

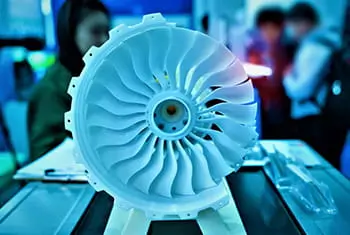

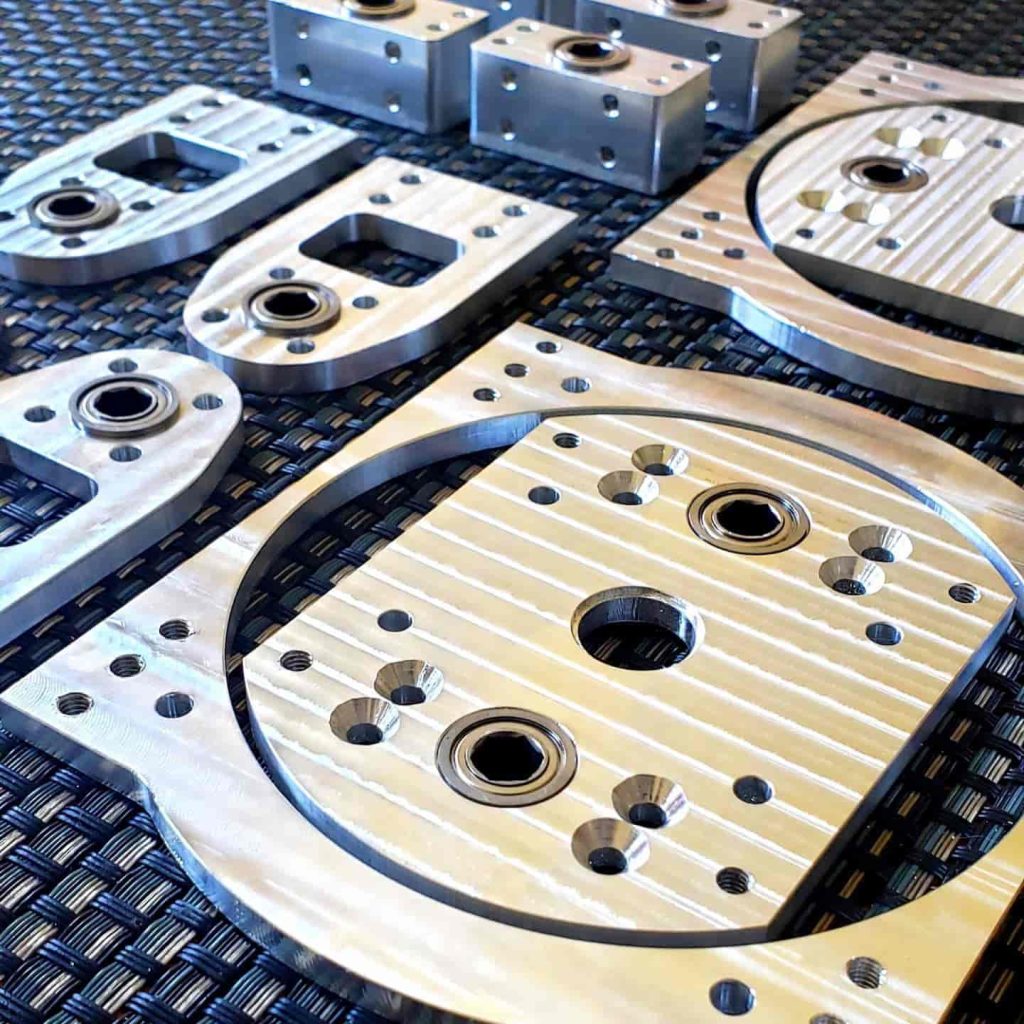

Robotic prototyping and parts manufacturing services facilitate innovative product development and new product introductions in the robotics industry. Get your products to market faster by leveraging leading-edge technology in specialized robotic component manufacturing.

On-Demand Robotic Manufacturing

Need some help taking your robotic device or model from sketch to reality? The creation of a robotic system may start with an idea, but requires extensive prototyping, testing, and production to achieve.

We are proud to provide industrial-grade robotic prototyping and parts manufacturing services to our global customer base. Xtmade is a prototype service provider that can work in the field of robotics. Our team of experts are able to provide high-quality rapid prototyping services quickly and efficiently.

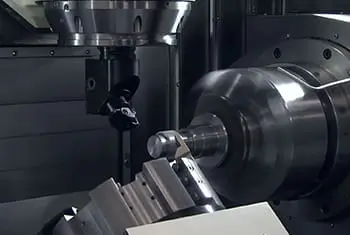

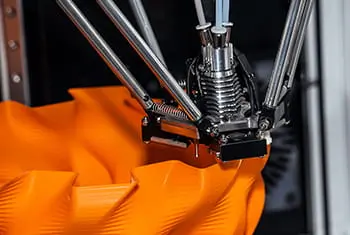

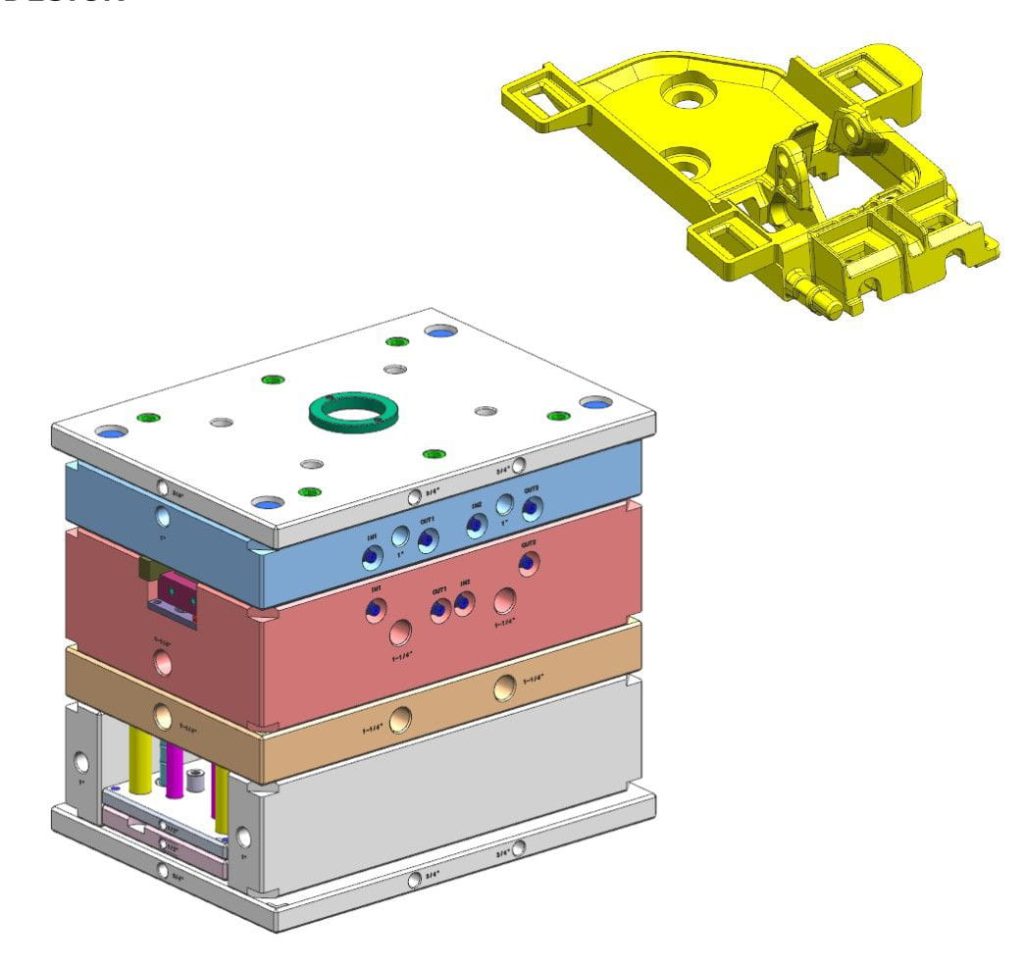

We offer a wide range of manufacturing technologies, including 3D printing, CNC machining, CNC milling, injection molding, casting, and other services. This way, we can ensure that your robotic prototype or part is produced with the right technology and materials, and we always strive to produce high-fidelity physical prototypes and pass rigorous validation and testing procedures.

Accelerate Innovation with Custom Robotic Manufacturing

Xtmade provides rapid prototyping and manufacturing solutions to meet the needs of the robotics industry. We offer reliable production services with short turnaround times and a high level of quality inspection, so you can expect your parts to arrive quickly and maintain quality. Whether you need prototypes or other parts manufactured for full-fledged robotic systems, you can count on Xtmade for timely delivery. Not only will we help you get your prototypes to market quickly, we’ll provide quality, precise products at an affordable price.

Robotics Manufacturing Capabilities

Our Material Options

Materials suitable for manufacturing robotic parts and components must be strong, lightweight, and tough. At Xtmade, our materials that meet these criteria include metals, thermoplastics, and composites. Materials suitable for use in the robotics industry should also be safe, flame retardant (when possible), and wear-resistant. Our common material choices for robotics manufacturing include:

- Nylon

- Ceramics and composites

- Natural Rubber, Synthetic Rubber, and Liquid Silicone rubber Thermoplastics

- Metal and metal alloy

- Aluminum

- Stainless Steel/Steel

- Titanium

- Brass

- copper

Perfect your parts with our finishing options

Surface finishing is an integral and critical part of the manufacturing of robots and robotic components. This is because robots have specific end functions, usually involving grasping, holding, gripping, etc. These functions require the robot’s attachments to have a certain smoothness, roughness, and texture. The right surface finish will allow them to perform their tasks effectively without causing damage to your products or business. Our finishing options also have other functions, such as aesthetics, attractiveness, and protection of the part surface. See below for a list of finishing options we offer for your robotic components and parts:

- Texturing

- Anodizing

- Polishing

- Insert installation

- Media blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

What we can do for you

Xtmade can manufacture high-quality tools, fixtures, and parts for your end-user robotics. Some of the CNC machining and 3D printing manufacturing services we provide for the robotics industry include:

- Robotic design

- Tooling and fixtures

- Custom housing and parts

- Chassis,enclosures, and brackets

- Part design and prototyping

- Generic and custom end-effectors

- Robotic modifications

- Tooling and jigs

- Custom housing and parts

- Custom robotic end-effectors

- Animal prosthetics

- Robotic parts and components

- Appendages (legs, arms)

- Fingers

- Racks

- Valves

- Stands

- Control boxes and adapters

- Sensors and actuators

- Internal hydraulic and hydraulic pump bodies

- Cable routing dividers

- Robot and manipulator prototyping

- Automated manufacturing systems

- processes, and techniques

- Robot-assisted medical devices

- Creation of smart factories

- Maintenance of industrial robots

- Custom fixturing

- Robotic prosthetics

- Robotic attachment and components

- Human prosthetics

The Clients We Serve

At Xtmade, we offer a range of manufacturing services that can serve every player in the robotics industry. Some of our popular clients fall into the following categories:

- Direct Robot Manufacturers

- Robotics-as-a-service (RaaS)

- Aftermarket robotic end-effector manufacturers

- Robotic engineers and design experts

- University robotic and engineering departments

- Industrial and general manufacturing

- Automobile engineers

- Robotics software experts

- Medical Robotics

- Autonomous mobile robots

- Service and diagnostic centers

- Aerospace robotics

- Exoskeleton component manufacturers

- Standalone, collaborative, and production line robots

- Articulated, SCARA, Delta, and Cartesian robot engineers

Put your parts into production today

Get started on your project with Xtmade! Send your completed CAD file to our team of quote engineers for a free quote. Once we receive your drawing, one of our design experts will contact you for a design review. We provide excellent technical and logistical support throughout the process, helping you refine your part design and discussing dimensional accuracy and part finishing.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…