Global delivery as fast as 15 days

Medical

New product development for the medical industry, on-demand manufacturing. From rapid prototyping to mass production of medical products, enjoy reliable manufacturing services at competitive prices.

We'll work with you from prototyping to production

Do you need help turning your medical product concepts into viable prototypes and production parts? Are you a medical device manufacturer looking for a manufacturing partner with extensive expertise in various technical fields to help you get your medical products and ideas to market faster?

Now is the time to take a closer look at what Xtmade has to offer!

Medical Device Manufacturing Solutions

The medical industry relies on product solutions custom to the highest standards. When safeguarding human health is the top priority, the quality of materials or processes in medical manufacturing can never be compromised. In addition, full transparency and traceability throughout the supply chain is essential to ensure that the finished product is free from contamination. We are proud to work with industry leaders to bring new products to market in the fields of clinical care, diagnostics, research and rehabilitation. Our success stories include fitness trackers, health monitors, drug delivery devices, medical device housings, prosthetics, and many other healthcare solutions. Xtmade has no minimum order quantity or value restrictions, supporting your design freedom. We are experts in providing custom medical prototyping and rapid product development solutions for projects of any size or complexity. Get to market quickly. Contact us today to learn how we can help you with our medical manufacturing services.

Innovate Faster With Custom Manufacturing for the Medical Industry

No matter how flawless your creations may look on paper, they don’t always translate into flawless parts. By leveraging the skills of the Xtmade team, you can achieve manufacturing perfection and streamline production while saving money and time.

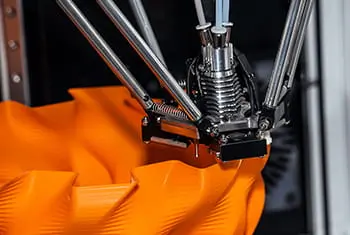

In the medical industry, prototyping is a critical step in the time-, cost-, and labor-intensive process of launching new products. The medical device prototyping process produces functional samples according to precise design and material specifications for use in product testing and evaluation phases and business demonstrations. These samples allow manufacturers to verify the validity and manufacturability of the design and determine if design changes are necessary before proceeding to mass production and market distribution.

We work with leading manufacturers serving the healthcare industry, including diagnostic laboratories and medical device companies. Our expertise in prototyping and medical device prototyping – coupled with our growing production capabilities in China.

Why Choose Xtmade for Your Medical Manufacturing Project

Ensuring supply chain reliability is critical to the medical industry. That’s why we use advanced metrology equipment to verify all raw materials and provide you with chemical analysis and full compliance certificates for your peace of mind. To meet the needs of the medical industry, we offer a range of materials including titanium, stainless steel, TPE, POM, PEEK, AB, nylon, silicone rubber, and more.

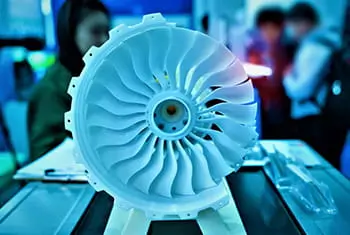

Medical Manufacturing Capabilities

Top Medical Device & Hardware Applications

Here are some of the types of medical parts we can manufacture for you.

- Prototypes

- Anatomical models

- Replacement parts

- Surgical instruments

- MRl and X-Ray

- components

- Monitoring equipment

- components

- Tables and panels

- Medical Carts

- Physiotherapy apparatuses

- Electronic equipment

- Components

- Prostheses

- Medical delivery systems

- Fluid management systems

- Biotechnology components

- Respiratory devices

- Handheld devices

- Diagnosis equipment

- Ultrasonic equipment

- Care equipment

Which Materials Are Suitable For Medical Applications?

- High Temperature Plastics: PEEK and PEl (Ultem) offer high temperature resistance, creep resistance, and are suitable for applications that require sterilization.

- Medical Grade Silicone Rubber: Dow Coing’s OPI-250 offers excellent heat, chemical, and electrical resistance. It is also biocompatible, so it can be used in applications that require skin contact.

- Carbon RPU and Fpu: Carbon DLS uses rigid and semi-rigid polyurethane materials to create functional pants that are ideal for late-stage prototyping or end-use devices.

- Microfluidics: Watershed (AB, etc.) and Accura 60 (PC, etc.) are clear materials that can be used for microfluidic parts and clear components such as lenses and housings.

- Medical Alloys: Between machined and 3D printed metals and sheet metal, there are more than 20 metal materials that can be used for medical components. Depending on the application, metals such as utanum and ncone offer high temperature resistance, while various stainless steel materials offer corrosion resistance and strength.

Surface Finishing Options for the Medical Industry

Xtmade offers a wide range of high-level surface finishes. We have listed only some of the common surface finish options. There are many more surface finish options for custom parts in the medical industry.

- As machined

- sanding & Polishing

- Sand, Bead Blasted

- Painted

- Powder coat

- Anodized

- E-Coating

- Nickel Plating

- Chromed

- Zinc Plating

- Chromate Conversion

- Coating

We are ISO 13485 certified

Xtmade is certified to ISO 13485, a management system standard designed for medical device manufacturing. This demonstrates that all medical device prototypes and components you receive from us comply with adequate regulatory requirements. It also demonstrates our quality control and assurance system, assuring you that we will manufacture components to your specific needs. We are ready to serve every customer in the dental, biotech, surgical and pharmaceutical industries, among others.

Material compliance

It is critical to ensure that materials meet regulatory standards such as biocompatibility and sterilization compatibility. The materials of many medical device components must comply with FDA, ISO and other relevant medical standards. Xtmade has a domestic material supplier channel that meets safety standards. For special materials, we also import raw materials from Europe and the United States to meet our customers’ product requirements and provide material certification reports to ensure that there are no material problems with the parts we produce. Our customers can rest assured that their medical products will be put on the market without any complaints.

Intellectual Property Protection

The security of intellectual property and technology is an aspect that cannot be ignored, therefore, it involves sharing ideas and sensitive information with partners who attach great importance to confidentiality agreements. In industrial applications in the medical field, signing a confidentiality agreement is a common means to protect the interests of customers. Xtmade will sign an agreement promising not to disclose confidential information of customer products without the customer’s permission. When you seek our help on any matter we handle, you will find that you have made the right choice.

Request a quote for your medical prototype project review now

Our team is dedicated to providing you with exceptional, efficient, and affordable rapid prototyping and manufacturing solutions. Our experience, expert team, and cutting-edge equipment enable us to take your ideas from design to market. To learn more about our capabilities or to help you prototype your next medical device, contact us or request a quote today.

Latest News

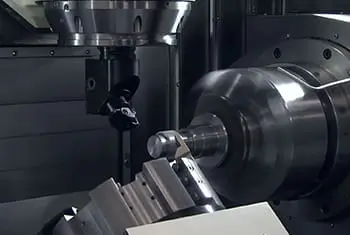

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…