Consumer product

To accelerate growth in the consumer goods industry, we provide consistent, accurate custom parts services to a wide variety of consumer product manufacturers.

Build and Test Consumer Products Faster With Manufacturing on Demand

We understand that the components we produce are at critical stages of pre-production testing, limited market release, and final production. Therefore, we work closely with customer design and procurement teams on every project to ensure high-quality components are delivered on time. We also follow a streamlined production process to ensure the right people are in place from design to part. Speed of development and a well-designed user-centric end product are critical to companies’ success in launching consumer products and devices to different markets. Technology-enabled manufacturing processes can speed up design cycles, reduce development costs, and help support consumer product companies in developing more products based on market demand.

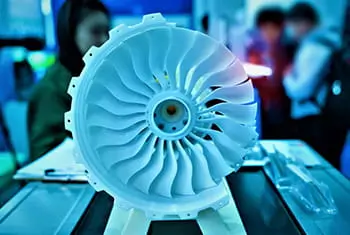

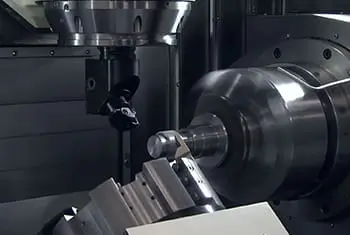

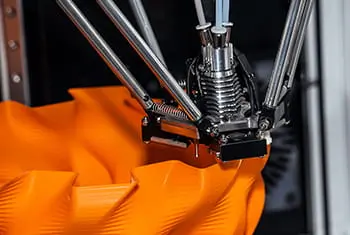

Custom Manufacturing Capabilities for Consumer Products

Xtmade offers a wide range of manufacturing processes for consumer product prototypes and production parts, achieving premium custom consumer goods through cutting-edge technology, proprietary processes and a commitment to quality.

Why Choose US

Testing and material verification to ensure quality

Consumer products need to meet many different international material compliance standards. This is to protect the health and safety of the end user and the environment. We take compliance of all our customers very seriously, which is why we have invested in advanced scientific testing and verification equipment to verify the conformity of all incoming raw materials.

Offering a range of in-house finishing services

Consumer products value beautiful finishes to stand out in a crowded market. We offer world-class finishes for your metal or plastic parts in millions of colors including matte, gloss, metallic, rubber, clear coat and more. We also offer anodizing, chrome plating or powder coating to achieve the look and performance you want.

Why do we need to develop product prototypes?

The business strategy of enterprises has shifted to “quick response to demand”, and the time factor is crucial. Under such an era background and requirements, the competitiveness of enterprises lies in how to create new product prototypes as quickly as possible to verify the design of product developers, and quickly iterate to bring new product ideas to market faster and attract target audiences. Product prototypes are like “toolboxes” for designers and engineers to verify whether the design meets the specifications or requirements defined in the prototype development process.

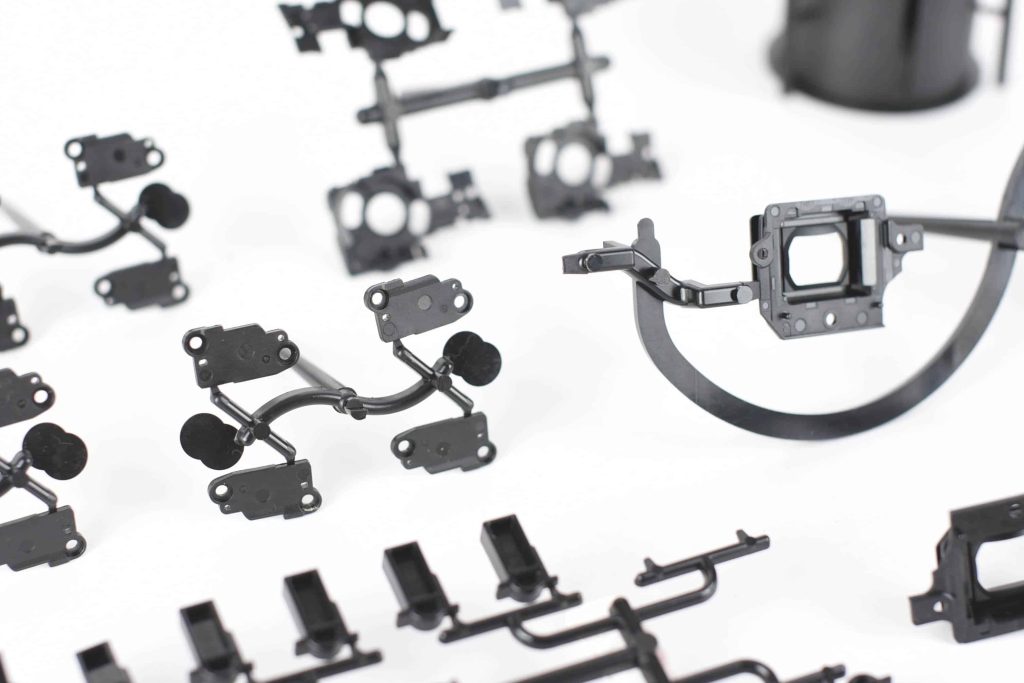

What type of product prototype is needed?

From idea to rapid prototype, it can be said that the early stage of product development from concept design to prototype development is a long and complicated process. However, before entering mass production, it is very necessary to verify whether the idea is feasible. The correct use of prototyping technology can make the product prototyping process more dynamic and effective, thereby reducing the possibility of failure. In fact, product prototypes can be verified throughout the design and development cycle, including physical prototypes, visual prototypes, working prototypes, and low-volume manufacturing.

Xtmade has an experienced design and manufacturing team, manufacturing systems, and our in-house factory to help customers custom the parts they need. As a result, we can produce custom parts for customers in the consumer goods industry in just a few days, reducing time to market, increasing development iterations, and maintaining flexibility longer before committing to high-volume processing. We can provide a variety of customer-required materials and a range of standard and custom textures. In addition, our team of engineers will perform stress and strain testing on prototypes to ensure that we can eliminate any factors that may cause the system we develop to fail. Other tests we perform include chemical resistance, mechanical properties, thermal properties, electrical properties, standard testing, and durability.

What kind of consumer products can we make?

In modern society, personalized and custom consumer products are the main demand of the current market. From design to unique color and material selection, Xtmade’s innovative manufacturing model provides you with advanced competitive advantages.

- Personal products

- Electronic devices housings

- Wearable devices

- Cookware products

- Athletics and sporting equipment

- Home Furnishings

- Smart home products

- Accessory components

- Virtual reality products

- Buttons

- Handles

- Knobs

- Switches

- Lenses

- Fixtures

- Consoles

- Heat sinks

Ready to get started? We make it easy

We encourage you to contact us regarding your next development project. Our team is ready to provide manufacturability analysis, design advice, and custom parts tailored to your needs.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…