Metal Fabrication

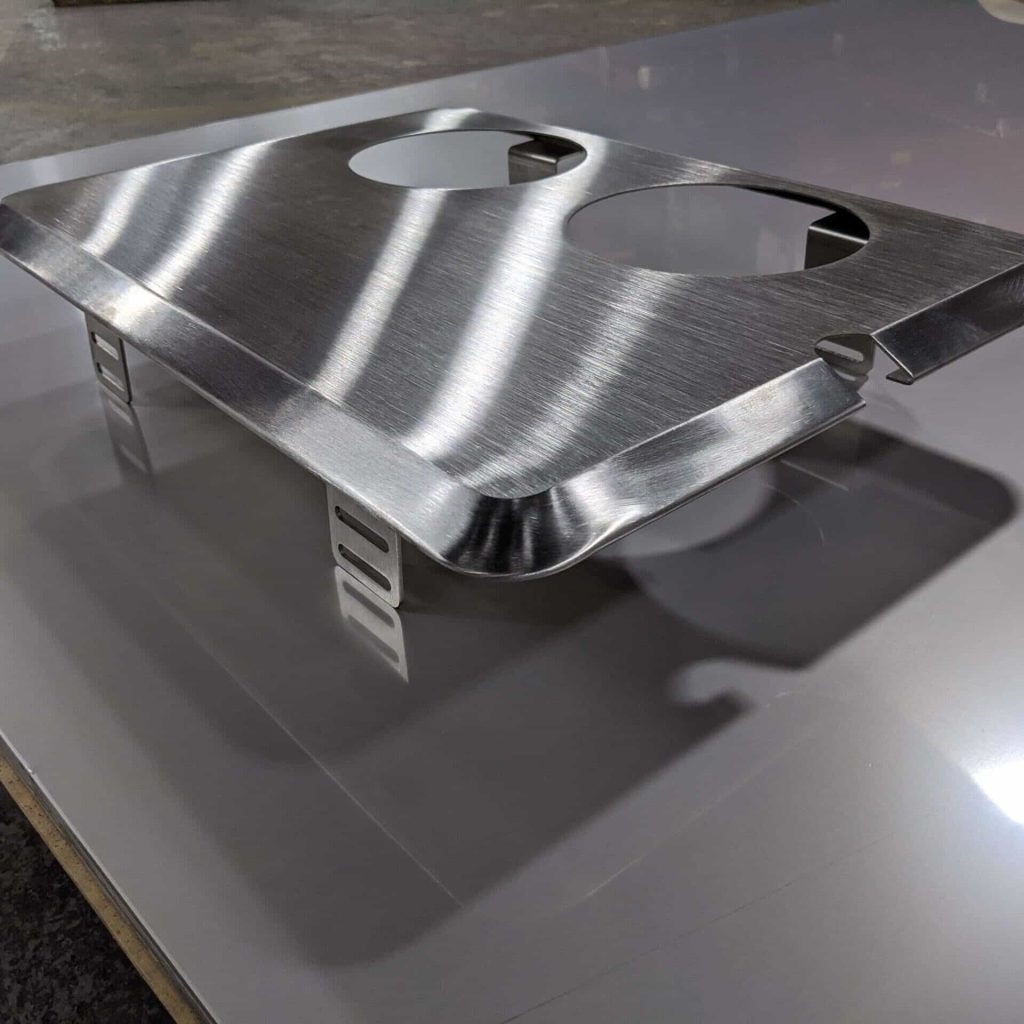

Sheet Metal Fabrication Services

Xtmade is a metal parts manufacturer serving OEM and their suppliers. Our services include fiber laser cutting, press brakes, CNC turret punching, welding, finishing, assembly and other metal forming services. Get a free quote now.

Committed!

Premium Metal Fabrication Manufacturer

Xtmade is a professional sheet metal manufacturer in Shenzhen, China. We serve companies of all sizes, from startups in need of prototyping to large enterprises seeking mass production capabilities. No matter what type of manufacturing your project requires, we have the advanced equipment and expertise to get the job done.

Our reputation is built on the skills of our experts and our commitment to certification and training. From design to finishing, from rolling to welding, we are able to complete every step of the manufacturing process in-house. This helps your company reduce manufacturing costs and allows us to control the manufacturing schedule.

Our capabilities include in-house tooling, precision stamping, laser cutting, machining, bending, punching, welding, and fabrication. With these advantages, we are able to coordinate your order requirements in a timely manner. Rapid prototyping and free design are our value-added services. Importantly, we are the factory, a direct source to reduce your procurement costs and ensure premium quality. We are equipped with high-precision equipment with an accuracy of +/-0.001mm and use Zeiss coordinate measuring machines for strict quality control. Our professional engineering team will conduct a comprehensive technical evaluation and develop an economical solution.

Design for Manufacturability(DFM) Feedback on EverySheet Metal Quote

We now provide automated design analysis for all sheet metal components, highlighting any features that may create challenges during manufacturing. DFM feedback that can improve the quality of sheet metal parts can now be provided within minutes.

Why Choose US

Metal Fabrication Services

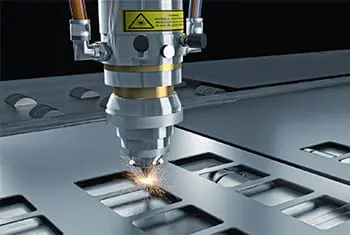

Laser Cutting

Metal stamping

Welding

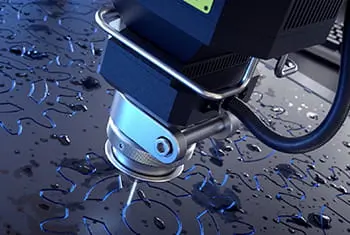

Waterjet Cutting

Sheet Cutting

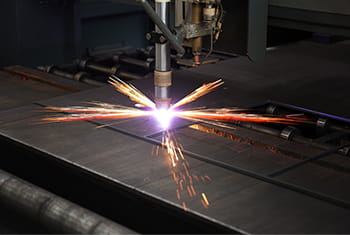

Plasma Cutting

Bending

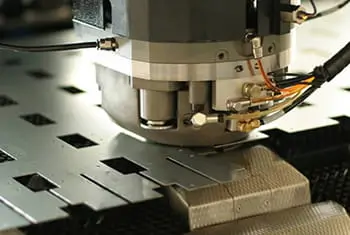

Punching

Riveting

Xtmade Sheet Metal Fabrication Capabilities

- Blank size: Minimum: 100mm x 100mm, Maximum: 3000mm x 3000mm

- Standard delivery time: 2 to 4 weeks, depending on material availability, design complexity and production schedule

- Sheet thickness: 0.5mm to 10mm

- General tolerance: ±0.5mm

- Braking (hydraulic): forces up to 200 tons, high precision for complex bends

- Braking (magnetic): suitable for delicate materials, smooth bends without marks

- Punching: processes steel, aluminum, copper; holes, slots and custom shapes available

- Welding: MIG, TIG and spot welding of stainless steel and aluminum alloys

Xtmade Sheet Metal Solutions

Rapid Prototyping

Our Rapid Prototyping service provides rapid prototyping of sheet metal parts, helping you validate designs and perform functional testing faster than ever before. It is ideal for making adjustments to designs and implementing them into your final product.

Low and High-Volume Production

Quickly adapt to market fluctuations with our diverse sheet metal production services. We specialize in handling custom orders, providing seamless scalability and on-time delivery. As production volumes increase, unit costs will decrease significantly.

How Does Xtmade Sheet Metal Fabrication Work

Xtmades extensive network of sheet metal fabrication shops ensures we have the capability to handle projects of any size. From complex prototypes to complete assemblies. We begin by meticulously converting your CAD design into precise machine code. Our fabrication shop team then expertly cuts, bends, and shapes the metal to meet your exact specifications. The process utilizes advanced manufacturing techniques such as welding, riveting, and fastening while adhering to strict quality standards. Our facilities are fully equipped to offer a wide range of finishing options, allowing each product to achieve not only functional precision, but also aesthetic excellence. Whether you require a single custom piece or large-scale production, our facilities are designed to efficiently and reliably deliver high-quality products, ensuring each project is the perfect fit for your requirements.

Materials

- Aluminum

- Brass

- Copper

- Steel

- Stainless Steel

Post-Processing & Finishing

Sheet metal parts often require post-processing to remove burrs or sharp edges and enhance their aesthetics. Xtmade provides the following post-processing services for sheet metal parts:

- Standard Raw Finish Options

- In-House Powder Coating & Silk Screening

- Anodize & Chromate

- Sandblasting

- Sanding and grinding

- Painting

- Powder coating

- Screen printing

- Assembly and kitting

Advantages

- Custom: Because sheet metal is easy to process, manufacturers can create custom metal parts to meet your precise requirements.

- Affordable: Sheet metal manufacturing is much less expensive than machining and offers a lot of flexibility in every step of the manufacturing process.

- Precision: Metal parts can be cut to exact sizes and shapes using computer-controlled equipment. This minimizes the need for secondary operations such as grinding and polishing.

- Scalability: Sheet metal forming can easily accommodate production changes without requiring a large investment in remodeling. This makes it ideal for creating prototypes and Low volume of parts for testing and validation. It is also a cost-effective option for producing small to medium batches of custom parts.

- Short Lead Time: Because sheet metal manufacturing does not require many processing steps, its lead time is generally shorter than other manufacturing techniques.

- Aesthetic Appeal: Sheet metal offers a variety of surface treatment options that can be used to enhance its appearance and prevent corrosion, including painting, powder coating, and anodizing.

Applications

Whether you need a few custom parts or a large production run, we can help. Some common product types we see in our sheet metal fabrication department include, but are not limited to, the following:

- Custom sheet metal enclosure boxes

- Electrical cabinet manufacturing

- Sheet metal steel skin manufacturing

- Custom metal control panel boxes

- Large sheet metal box fabrication

- Custom sheet metal covers

- Custom metal bracket fabrication

- Steel frame housings

- Custom frame members

- Custom metal frame welding

- Adapter plate fabrication

- Custom chassis welding fabrication

- Complex large weldment fabrication

- Mechanical sheet metal assemblies

- And many more sheet metal parts and fabricated components

Industries We Serve

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Let's Get Your Project Underway!

Xtmade sales engineers can help you determine a cost-effective solution for your sheet metal fabrication project.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…