Systematic LSR solutions

Liquid Silicone Rubber (LSR) Injection Molding

Xtmade meets the needs of our customers by providing high-quality, reliable custom LSR injection molding solutions. Including: design, prototyping and manufacturing of complex components. Contact us now for a free quote.

Turnkey Capabilities

Professional LSR Injection Molding Manufacturing Company

Xtmade has been dedicated to meeting our customers’ needs for custom molded rubber. Our expertise allows us to provide solutions for difficult applications. Whether your needs are for 10 pieces or millions, we will build a partnership with you from the beginning. This way, we can work as a team to meet your exact needs. Your specific requirements are considered at every stage of the project.

If you are looking for a proven design-to-injection molding manufacturing resource for your custom LSR project, our company has you covered. And, the experts in our advanced materials lab can help you make the right material selection. When you contact us, one of our engineers will help you determine if the on-spec requirement is the right choice for the application, or if an alternative off-spec material choice will provide a higher level of quality, reliability, and performance for the final product. Contact us today for support and a free quote.

Why You'll love working with us

At Xtmade, we take on challenges and use our rubber engineering experience to create a custom solution just for you. But it’s our can-do attitude and short turnaround times that keep our customers coming back for more.

Advanced Manufacturing Technology

Experienced designers and engineers

Shorter delivery time

Easy to do business

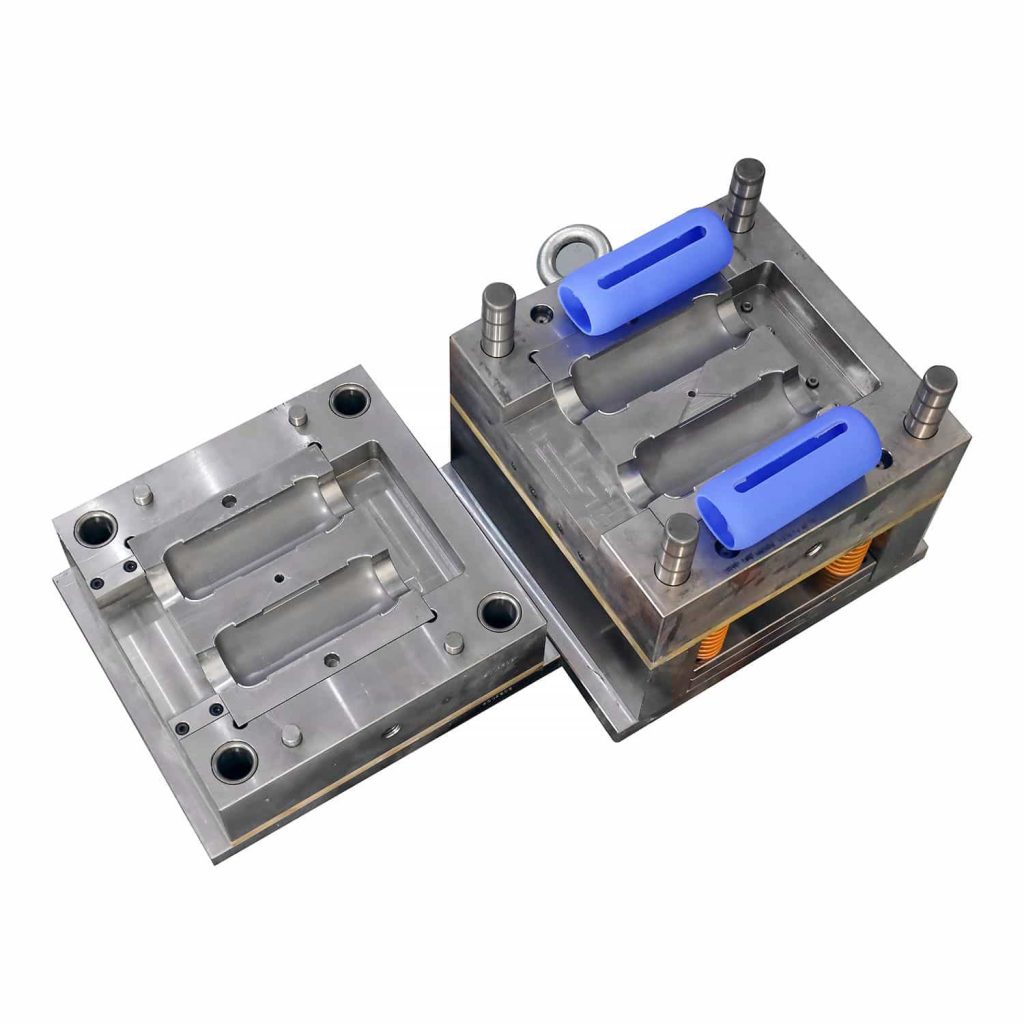

Liquid Silicone Rubber Molding Capabilities

Our basic guidelines for silicone rubber molding, including important design considerations to help improve part moldability, enhance appearance, and reduce overall production time.

- Dimensions: 304.88mmx203.2mmx101.6mm

- Volume: 217,948 cubic millimeters

- Depth: No more than 50.88mm from any parting line; deeper parts are limited to smaller profiles

- Estimated mold area: 30968 square millimeters

- Tolerances: Xtmade can maintain machining tolerances of +/- 0.003 inches (0.08mm), with linear tolerances of +/- 0.025 inches/inch (0.025mm/mm)

Xtmade comprehensive service

Xtmade specializes in custom injection molded Liquid Silicone Rubber (LSR) parts, LSR overmolded parts, and LSR 2-Shot (LSR/thermoplastic) and Multi-Shot assemblies. Our team of experts has many years of knowledge and experience in injection molding LSR. We provide greater value to our partners by offering a full range of services from early design and prototype support to custom manufacturing processes and quality systems, providing custom solutions to meet the specific needs of each project, and delivering high-precision, high-volume, and high-quality Liquid Silicone Rubber and LSR Multi-Shot molded assemblies.

We'll Help You Avoid and Mitigate Signifcant Risks in LSR Projects

We work with you early in the project to help you consider quality and certification, avoiding rework that can add cost and delay your project. You can count on us to:

- Consult with you on prototypes to consider long-term production engineering needs.

- Help you consider all material options before moving on to the next phase of your project.

- Review key functional features with you, such as parting lines and gate locations.

- Help you develop specifications, ensuring they are not overly restrictive.

The more we collaborate and share information, the better our experts can help you anticipate your needs and avoid and mitigate project risks.

Designing and Creating LSR Prototypes with Manufacturingin Mind

We work with you early in the project to focus on quality and better understand the design input and output requirements of your custom part. Giving us a better understanding of the design intent of your product will result in a smoother product launch and significantly reduce future risk. Examples of questions we will help you answer include:

- Do you need an early prototype or a manufacturing-quality replica prototype?

- How many cavities are required in the tool to support the volume required for development?

- Where are your critical sealing surfaces and functional areas?

- Where can we place gates and parting lines?

- What are the general operating conditions for temperature, fluid contact, cycle rates?

Unlimited design capabilities

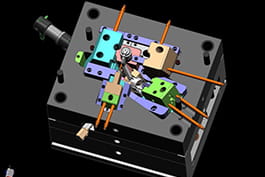

We rely on in-house tooling and advanced process engineering to improve quality and ensure tight tolerances are consistently achieved while providing our customers with the lowest cost of ownership.

We are your go-to manufacturer for custom molded rubber and silicone products

Xtmade can take your project from prototype to finished product production. You don’t have to involve another company in the production process. Some of the services we offer include:

- Complete silicone molding service from prototype to production.

- Your custom tooling is made in-house from 4130 steel, creating precision steel tooling at the right lifecycle cost.

- Our custom molding services include injection molding, transfer, and compression molding capabilities.

- The production of overmolded parts is not just a major part of our business. It’s our specialty.

- Our custom rubber molds can be used for high or low volume production, we don’t shy away from very large orders, and we proudly accept small orders.

- We offer a variety of services including rubber to metal bonding and custom silicone to metal bonding projects. We can bond a variety of custom formulations to materials such as brass, aluminum, steel and even glass filled nylon to meet your needs.

Application

Some applications that benefit from LSR injection molding include:

- Medical device and patientinterface components

- LED lenses and optics

- Electrical connectors and seals

- Infant bottle nipples, pacifers,and toys

- Plumbing gaskets and seals

- Soft touch buttons/handles andappliance components

- Consumer goods

- Food and beverage preparation,dispensing and utensils

Advantages of Liquid Silicone Rubber (LSR) Molding

LSR injection molding offers custom manufacturing opportunities and is a popular solution due to its ability to mold complex part geometries, excellent mechanical properties and purity. Other benefits include:

- High tear strength.

- Great optical clarity to maximize light transmittance.

- UV resistant.

- Biocompatible.

- Low compression set.

- Excellent chemical resistance.

- Withstands harsh environments ranging from low to high temperatureextremes.

- Ability to overmold and bond onto a variety of substrates, such asplastics and metals.

- Customizable additives such as antimicrobial, electrical conduction, self-lubricating and antistatic.

Industries We Serve

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Contact us now to get technical support from our LSR injection molding engineers

We provide you with LSR injection molding solutions, from design to tooling to material selection and manufacturing. Contact our professional team now to solve your problems.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…