Make Strong, Functional Prototypes and Production Parts

Insert Molding Service

Custom insert molding services for high-quality prototypes and on-demand parts. Get a free quote with competitive pricing and short lead times.

Strong And Sturdy

Specializing In Insert Molding Services

We are a factory business that provides engineering, custom injection molding and contract manufacturing services. Our customers bring demanding applications that require insert molding services, and our professional engineers provide a complete service. All of our injection molding machines are capable of high-speed automation and production insert molding services. Our engineers have expertise and experience in areas such as medical mold design and manufacturing, high-volume automation for consumer packaging, and engineering grade resins and ultra polymers in electronics.

Expert Solutions for Your Insert Molding Needs

Do you have a project that needs customization? With insert molding, you can get the perfect component for your concept manufacturing needs. Xtmade offers custom insert molding to help you turn your final product into reality. Our experts will work with you to provide high-quality results in a short period of time.

During this process, we will use a robotic arm to insert the metal part into the mold cavity to achieve a specific shape. Then, we allow plastic to enter the mold, cover the metal part and form the desired shape.

The main purpose of insert molding is to combine the desired characteristics of metal and plastic into one product. Common applications for insert molding include wires, insulation tubing, and tools such as screwdrivers. Manufacturers often use insert molding to protect metal parts with a durable plastic layer.

Range of Mould Making Options

Our certified injection mold making shop allows us to quickly transform your 3D part data into high quality injection molds. We offer design and manufacturing services from tools and molds to prototyping and production runs. Plastic blow molds, aluminum and steel molds, 2 and 3 shot molding are also available. With Xtmade, you own your own tooling, so our shop can also provide mold care services.

Design Guidelines for Insert Molding Services

Our insert molding services enable you to manufacture parts that meet a variety of functional requirements. We ensure the quality of your insert molding projects by following molding design requirements executed in a specific manner.

Machining

We have high-volume injection molding machines designed to perform the plastic molding process through insert molding and have a set of design guidelines that are accurately followed by our experienced and professional engineering team. The machines we use for insert molding have very tight tolerances, which ensures that the information of the plastic part is accurate in plastic injection molding. We know that even a tiny misalignment of the millimeter level will eventually lead to product failure, which is why we ensure that there is no margin for error.

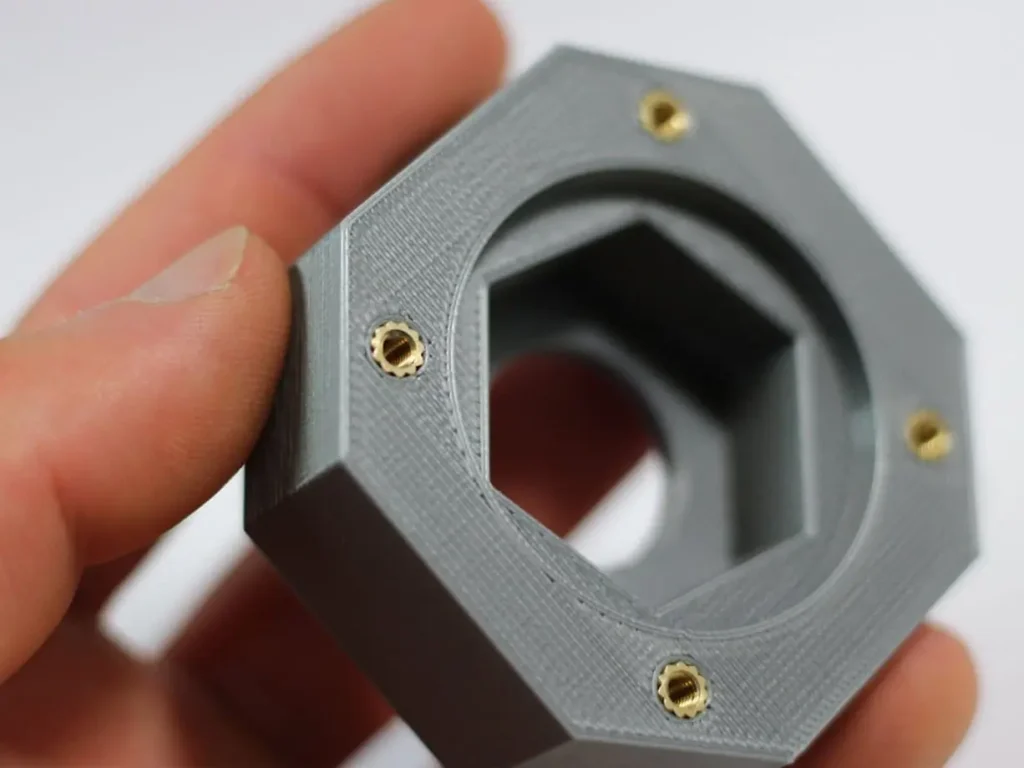

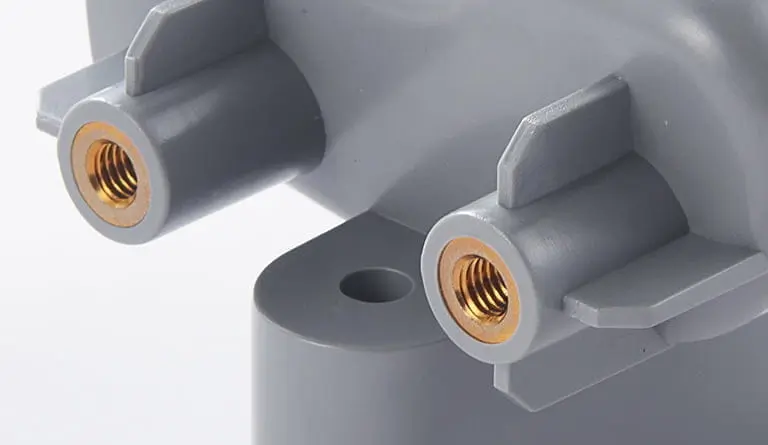

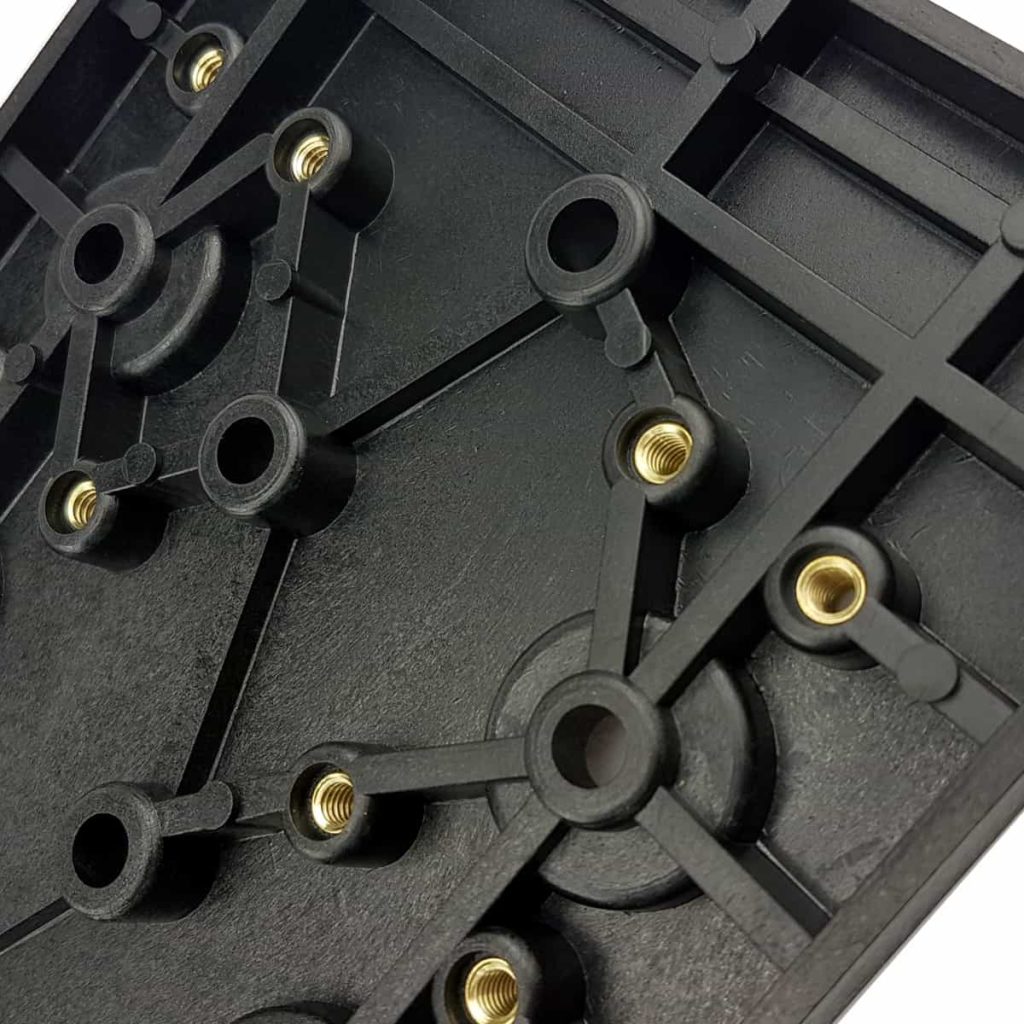

Inserts

There are many different types of inserts that are used when designing and manufacturing molded parts. These metal inserts in insert molding are usually made of brass, stainless steel, or regular steel. The mold is placed vertically in the machine either manually or automatically through CNC machining. The vertical position is to ensure that the mold remains safely in place during the insert molding process with the help of gravity. The molten plastic is now poured into the mold and the mold is closed.

Threading Options

The threading option allows the manufacturer to place pipes, screws, or anything else in a specified location on the mold. The purpose is to ensure that the mold does not dig into the product. Since the product needs to be connected to external conduits in various ways, the mold will keep the final product functional and practical.

Insert Molding Pioneers

We have years of experience handling the complexities of insert molding and providing turnkey solutions to our customers. As with all injection molding, early involvement in the design process can result in significant savings in tooling costs and part prices. Contact us today for a quote

Materials used for insert molding

The following are the most commonly used materials for insert molding:

- ABS

- ABS/PC

- Acetal

- Delrin

- ETPU

- HDPE

- LCP

- Nylon

- PBT

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- PMMA

- PPA

- PPE/PS

- PS

- PSU

- TPU

- LDPE

- Polycarbonate

- Polypropylene

Insert material

Insert molding is commonly used to embed screws or studs. Brass is a commonly used material in insert molding because it does not rust, is corrosion-resistant, cheap, and easy to process.

In addition, copper, aluminum, steel, hard heterogeneous plastic parts, ceramics, glass, plastics, etc. can all be used as insert materials. In product applications, we will design the shape and structure of plastic parts based on the thermal expansion coefficient of different materials.

Finishing Options

Molded parts can be finished in a variety of ways, either to cover a purely aesthetic surface or to provide some form of protection. Finishing should beautify and enhance the sophistication and functionality of any part. At Xtmade, our injection molded parts can be finished in any of the following ways:

- As-is: Also known as “as-machined”, the part will be the same as when it was molded, with tool marks still visible. This finish is suitable for parts that do not have any aesthetic emphasis or to hide industrial parts.

- Shot peening: Shot peening is used to level the surface of machined parts and create a uniform finished surface.

- Pad printing: Pad printing is a decorative technique used to transfer ink markings, logos or text from a pad printing station to a part.

- Etching: Etching is a method of engraving a pattern, mark or text on the surface of a molded part.

- Textured finishing: The molded part is leveled with fine stone powder before blasting to achieve a textured surface appearance. Suitable for parts that require a dull or satin finish.

- Laser finishing: The use of a laser beam to etch, carve or engrave graphics, text, logos or markings on a molded part.

- Semi-Gloss: Semi-gloss parts have a lower gloss and require sanding with fine sandpaper to achieve gloss.

- Gloss: Gloss finishes are used to achieve a mirror-like smooth finish in molded parts. Parts are ground and polished with a diamond polishing wheel. These parts have the smoothest surface compared to other finishing options.

- Matte: Matte finishes are suitable for removing machining marks on molded parts without overly affecting the appearance. The mold is smoothed with the help of fine stone powder. Matte finishes are suitable for die-cast or thermoset injection molded parts.

- Custom: Choose from a range of unique custom finishes or a combination of some standard finishes.

What is Insert Molding?

Insert molding is the process of molding or forming a plastic part around other non-plastic parts or inserts. The inserted parts are usually simple objects such as threads or rods, but in some cases, inserts can be as complex as batteries or motors.

In addition, insert molding combines metal and plastic or multiple materials and components into a single unit. The process utilizes engineered plastics for wear resistance, tensile strength and weight reduction while utilizing metallic materials for strength and conductivity. The benefit is that parts can be mass-produced faster than if the entire part were machined from metal. While insert molding increases cycle time, it is still much faster than CNC machining a part from a solid block. Additionally, by insert molding metal where necessary and replacing the rest of the part with plastic will in turn reduce the overall weight of the part.

Insert Molding vs.Overmolding

Insert molding and overmolding are two different processes, each producing different products. The overmolding process involves molding one material over another. The base layer is molded first, and then additional layers of plastic are molded over and around the original part. This creates a finished product. Overmolding produces a durable, long-lasting, and safer finished product.

In contrast, insert molding involves injecting an insert material into the mold cavity before injecting the plastic into the mold. The final product is a single part with the insert encapsulated by the plastic. Plastic injection molded inserts offer a cost-effective assembly process that produces smaller, lighter parts.

Insert Injection Molding Benefts

Insert molding is a type of injection molding process that works especially well for parts with threaded holes. It can also help you make better wheels, pulleys, fan blades, and other similar parts. When done correctly, insert molding can help:

- Eliminate assembly: You can make insert molded parts in one go, without having to assemble them afterwards

- Reduce costs: Insert molding costs more than standard injection molding, but the cost is usually offset by the fact that you no longer have to assemble them afterwards.

- Reduce part size and weight: Plastic parts with metal inserts are often lighter than aluminum metal parts.

- Increase reliability: Metal mold inserts will ensure the functionality of the threads and reduce wear over the life of the part.

- Increase part strength: Because it is a “one-shot” process, it can produce stronger parts than overmolding and other processes.

Industries We Serve

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Ready to start your next insert molding project?

We’re ready to help you with your project. Contact us today and let’s get started.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…