Plastic parts manufacturing

Injection Molding Services

With our unique combination of superior skills and expertise, we can manufacture plastic parts to your needs and preferences. We work with you to provide a comprehensive range of custom injection molding services. Accelerate iterative testing and scale production. Upload your design, get DFM feedback and quotes now.

Meeting your fast tooling and low-volume production needs

We have the experience and equipment to deliver processing efficiency, flexibility, and support. We leverage our exceptional molding expertise to provide comprehensive technical guidance and tooling options for your project. We don’t just send a price estimate for a new project; we send an informed quote after understanding your needs. We work closely with you from the beginning to ensure the job specifications meet your project goals.

In addition, we provide fast-turnaround injection molding services without sacrificing quality or precision. We are constantly improving our production processes, implementing new methods to reduce inefficiencies and shorten lead times for our customers. Whether you are looking for short-run production, rapid tooling, or prototyping services, we can help you find the right solution and deliver it quickly and efficiently.

We understand the complex needs of customers for various plastics

Xtmade offers a wide range of plastic injection molding services to meet your needs. We are industry experts who continually seek to improve our reaction injection molding process by contributing significant design knowledge and capabilities.

Each of our members is dedicated to making your RIM design a success at every stage of the production process. From part and CAD design to mold design, fabrication, part production, secondary operations, painting and screen printing, assembly, packaging, shipping, and more, we will service your project.

Explore Our lnjection Molding Service

Insert Molding

Overmolding

LSR Molding

Injection Molding Materials

We produce high quality plastic injection molded parts, Xtmade offers common metals and a variety of popular plastic materials for injection molds. If you are looking for alternative material options, contact our team of engineers today.

Hard Plastics

- ABS (Acrylonitrile ButadieneStyrene)

- ASA (Acrylonitrile StyreneAcrylate)

- CA (Cellulose Acetate)

- COP0 (Copolyester)

- PCTI (Polycyclohexylenedimethylene Terephthalate)

- PPA (Polyphthalamide)

- HDPE (High-Density Polyethylene)

- PEEK

- Polypropylene (PP)

- Polycarbonate (PC)

- PMMA (Polymethyl Methacrylate, Acrylic)

- Nylon 12(PA12)

- Nylon 6/66(PA6/66)

- Derlin (PoM)

- Teflon (PTFE)

- PBT

- PLA (Polylactic Acid)

- High-Density Polyethylene(HDPE)

- PVC

- PPS (Polyphenylene Sulfide,Ryton)

- Vespel (Pl)

- Torlon 4203 (PA)

- UPE/UHMW

- PVDF

- ULTEM (PEI)

Mixed plastic

- PC-ABS (Polycarbonate-Acrylonitrile ButadieneStyrene)

- PC-PBT (Polycarbonate-PolybutyleneTerephthalate)

- PC-PET (Polycarbonate-PolyethyleneTerephthalate)

- PS-PPE (Polystyrene-Polyphenyl Ethers)

- PE-PS (Polyethylene-Polystyrene)

- PE-PP ( Polyethylene-Polypropylene)

- PBT-PET(Polybutylene Terephthalate-Polyethylene Terephthalate)

Rubber-Like Varieties

- TPE (Thermoplastic Elastomer, Santoprene)

- TPU (Thermoplastic Polvarethane (Shore A)

- LSR (Liquid Silicone Rubber)

- PVC (Polyvinyl Chloride (Shore A))

- POE (Polyolefin Elastomer)

- MPR (Melt Processable Rubber)

- EPDM (Ethylene Propylene Diene MonomerRubber, Viton)

Flexible Plastics

- Polyethylene (PE)

- Polystyrene (Ps)

- PET

- EVA Foam

- EPS Foam

- PU Foam

Ready to Get a Custom Injection Molding Quote?

Overview of our injection mold making services

Our core competitiveness in mold manufacturing is reflected in the following three stages:

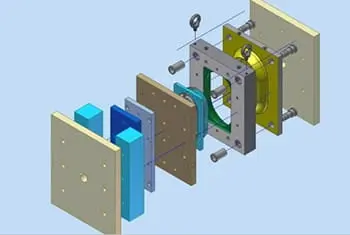

Mold Design

Mold Machining

Mold assembly

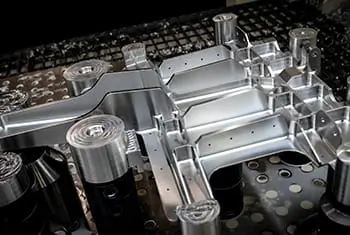

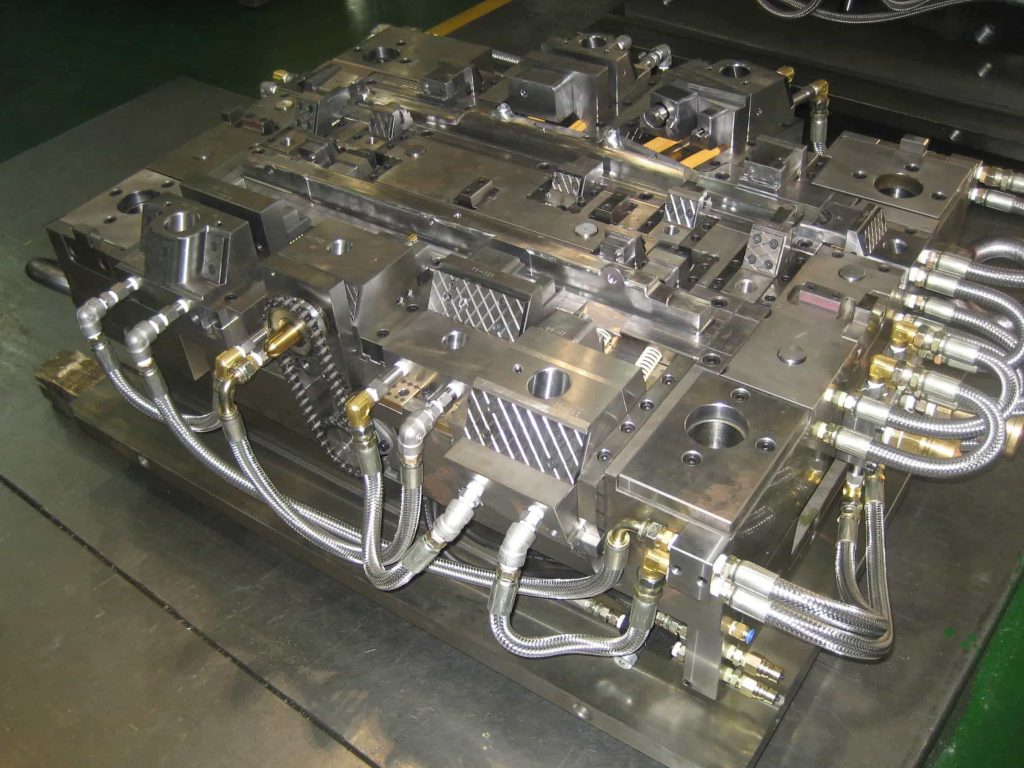

Precision Mold Manufacturing Technology

In our facility, we utilize cutting-edge technology to provide high-precision custom injection molds. Our factory-customized equipment allows for complex designs, ensuring impeccable accuracy and repeatability in the mold manufacturing process. By utilizing advanced technology, we guarantee that molds meet or exceed industry standards, resulting in superior product quality and performance.

Tailor-made Product Design Solutions

We understand that every product design is unique, with specific requirements and challenges. Our factory-made custom injection mold solutions provide the flexibility to meet these individual needs. We have a dedicated team of engineers who work closely with our customers to fully understand their design goals and complexities. This personalized approach ensures that the mold design is optimized to produce a product that meets or exceeds expectations while reducing production time and costs.

Injection Mold Types

We can manufacture injection moulds from aluminium (ideal for rapid low volume prototyping) or tool steel. The moulds comply with the SPl mould classification which specifies the durability of the mould and the number of cycles it can handle.

Standard injection mold tools are categorized from Class 105 (prototype) to Class 101 (high volume production). These tooling categories help manage customer and supplier expectations regarding overall tooling requirements and scope.

Over 1,000,000 cycles. They are designed for extremely high production volumes. These are the highest priced molds and are made with only the finest quality materials. 101 grade molds are also known as l-grade tools. Example: Multi-cavity steel tool with full automation and night work center for dedicated part manufacturing.

Medium to high production tooling for abrasives or parts requiring close tolerances. This is a high quality, reasonably priced tooling. Grade 102 tooling is also known as Grade ll tooling. Example: Steel tooling with SPl A-2 surface finish, automatic slide, scheduled production cycles.

Less than 500,000 cycles. Medium production tooling. This is a very popular tooling for low to medium production needs. Most common price range. Also called Class III tooling. Examples: Aluminum or steel tooling, automatic lifts or slides, multiple repeat run batches between 1,000-5,000 units.

Less than 100,000 cycles. Low production tooling. For limited production only, preferably with non-abrasive materials. Price range is low to medium. Grade 104 tooling is also known as Grade IV tooling. Examples: Aluminum or MUD tooling, SPl B-3 finish, hand loaded cores, and limited heavy runs.

Less than 500 cycles. Prototypes only. This mold will be manufactured at the lowest possible cost to produce a minimum number of prototype parts. Class 105 molds are also known as Class V tools. Example: One-off market test of 100 molded units.

What is Injection Molding?

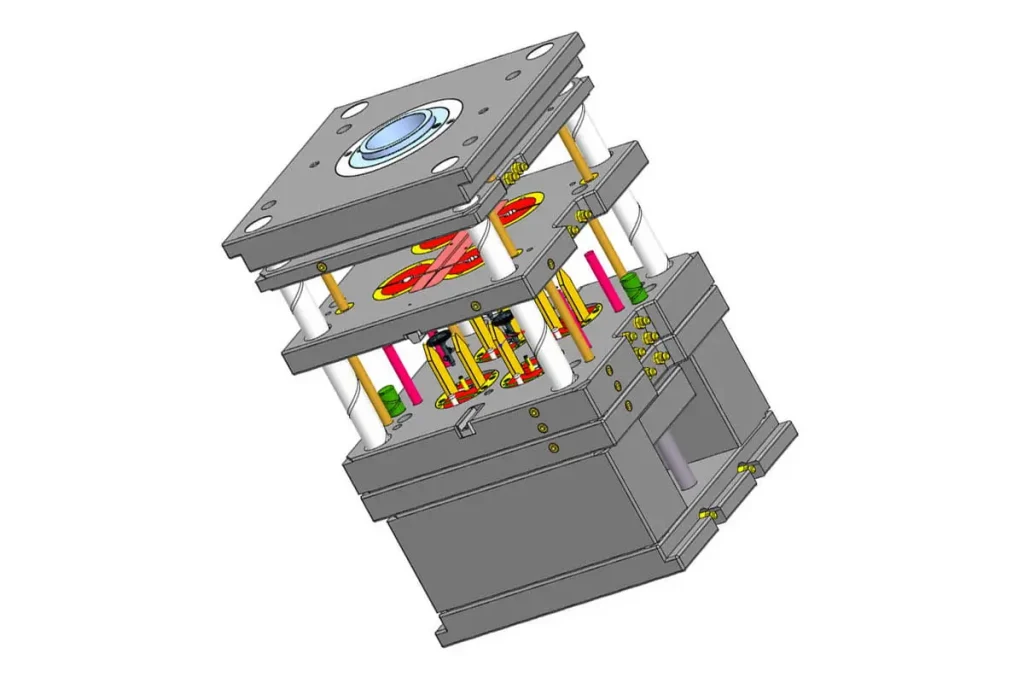

The injection molding process begins with plastic resin pellets. The resin is heated to a molten state and then shot into the mold. The plastic pellets are loaded into a hopper, which feeds the injection molding machine. The pellets are gravity-fed from the hopper into a heated chamber (called a barrel), where they are melted, compressed, and injected into the mold’s runner system by a reciprocating screw. Runners are channels in the mold that deliver molten plastic to the mold cavity.

The pellets are slowly moved forward by a spiral plunger, and the molten plastic is forced through a nozzle connected to the mold’s gate bushing, which controls the flow of material into the mold cavity through the gate and runner system.

The metal mold is kept at a lower temperature, so the plastic solidifies almost immediately after the mold is filled. The part cools and hardens into the shape of the mold cavity. The two halves of the mold, the A and B sides, or the cavity and core, open, and the ejector pins push the part out of the mold, and the part falls into a box. The mold is then closed and the process begins again.

Advantages of Injection Molding

- With plastic injection molds, you can produce large quantities of uniform, complex parts and geometries.

- Injection molded plastic parts are compatible with a wide range of colors and materials, including resins, silicones, thermoplastics, and thermosets.

- The injection mold is one of the strongest guarantees that the part matches the original. This not only ensures product quality and part reliability, but also reduces plastic material waste.

- Injection molding is a solution for scaling up large-scale or batch production due to its simplicity and consistency. Standardized injection molds allow manufacturers to produce to the specific requirements of their products and replicate them quickly and accurately.

- Products produced through injection molding can keep costs low. The more parts produced, the lower the unit cost, which makes plastic injection molding particularly suitable for large-scale production.

Focus on small and medium-volume orders

Low-volume plastic injection molding is primarily driven by customers with continuous product development cycles or low product demand. Xtmade works with product developers, OEMs, and Tier 1 suppliers to deliver plastic injection molded parts that meet tight specifications, timelines, and budgets.

Our low-volume molding customers highly value supplier relationships and leverage Xtmade as their preferred partner for plastic product development to troubleshoot, propose solutions, and share practices in tool design and optimized processing for repeatability time and again.

Our customers consider giving their next plastic development project to Xtmade because they have experienced firsthand what our team can offer!

Industries We Serve

We serve companies across many industries, including automotive interior and exterior accessories, medical device components, safety components, and more.

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Want to start your injection mold project now?

We provide high standard injection molding services, support short delivery of low volume manufacturing, and respond quickly within 24 hours.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…