CNC PROCESSES

CNC Milling Services

Xtmade’s 3-axis and full 5-axis milling centers, advanced quality assurance systems, and our experienced team of professionals are ready to complete any challenging machining job for you. Upload your CAD file and get an instant quote in seconds.

Custom CNC Milling

Our Service

Let us bring your product design or idea to life with premium custom CNC milling services. We offer custom CNC milling services for all designs and a wide range of metals and plastics. Using our state-of-the-art multi-axis machines, our team of highly qualified engineers and machinists can quickly complete your product. We also have a dedicated quality control team that tests and ensures that all CNC machined parts meet our customers’ requirements and required standards and regulations. Our CNC milling services complement our many other manufacturing and finishing capabilities to provide a comprehensive and satisfying solution for your product development project.

Our Factory Division

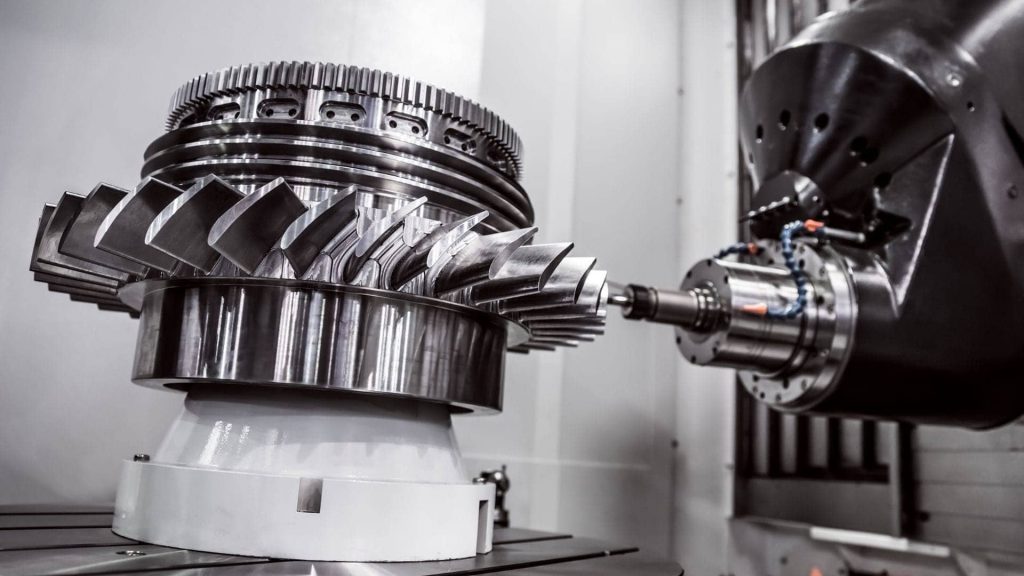

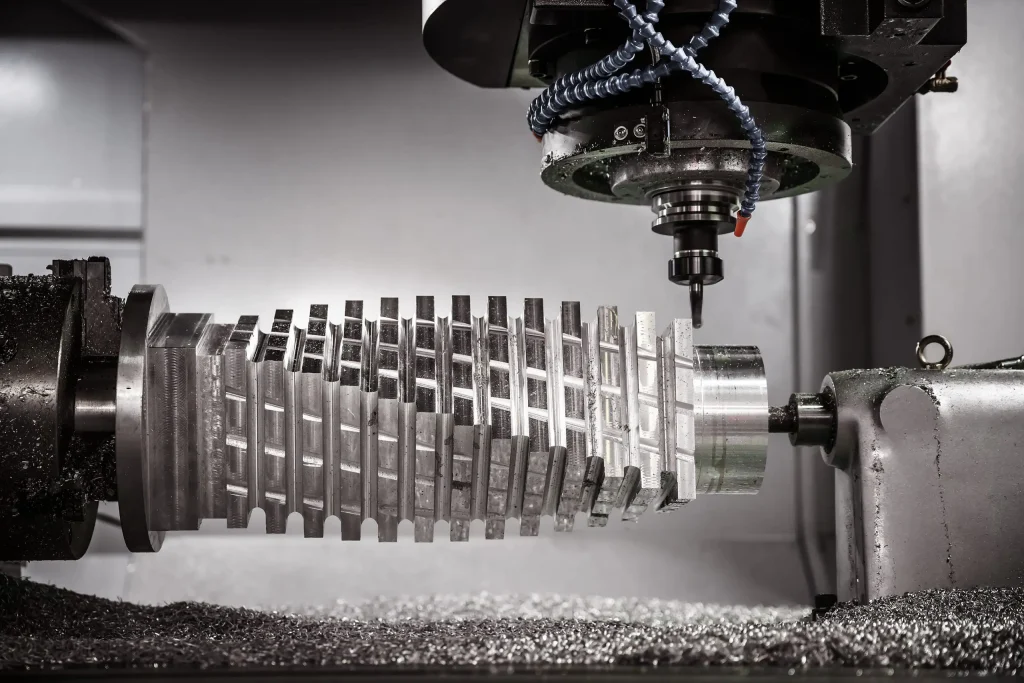

Our Production Milling division has the equipment, personnel, software and automation to produce your parts quickly and consistently. We offer 3-axis, 4-axis and simultaneous 5-axis machining to mass produce milled parts of any complexity or material. Our 40+ milling machines, including 3-axis, 4-axis and 5-axis CNC milling centers, enable the production of rapid prototypes and low-volume precision parts with highly functional and complex geometries. CNC milling is ideal for manufacturing parts with flat and jagged geometries such as slots and grooves, as well as post-processing to add detail to turned, 3D printed or molded parts. We specialize in producing functional parts such as brackets, gears, accessory housings, molds, engine parts, medical devices, punches and dies, making them ideal for many industries.

CNC Milling Processes

3- and 5-axis milling, delivery time from 5 days

3-Axis CNC Milling Service

Widely used type of CNC milling machine. Taking full advantage of the X, Y, and Z directions, 3-axis CNC milling machines can be used for a wide variety of jobs.

4-Axis CNC Milling Service

This type of router allows the machine to rotate on a vertical axis, moving the workpiece for more continuous machining.

5-Axis CNC Milling Service

These machines have three conventional axes as well as two additional rotary axes. Therefore, a 5-axis CNC router is able to machine 5 sides of a workpiece in one machine without having to remove the workpiece and reset it.

Ready to get started on your cnc milling quote?

CNC Milling capabilities

Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult Xtmade’s Manufacturing Standards. |

Precision Tolerances | xtmade can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and callouts. |

Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

CNC Milling Materials

We stock over 100 production-grade plastic and metal materials for a wide variety of part applications and industries.

- Aluminum

- Brass

- Copper

- Stainless Steel

- Alloy Steel

- Steel Mild Low Carbon

- Titanium

- ABS

- Acetal

- Acrylic

- CPVC

- DELRIN

- HDPE

- Metal detectable

- Nylon

- PEEK

- PET

- PETG

- PFA

- Phenolic

- Polycarbonate

- Polypropylene

- PPS

- PTFE

- PVC

- PPE (Tecanyl MT)

- Polystyrene

- Rulon

- UHMW

Finishing options

In addition to our standard high-quality deburred surface finishes, we offer additional options both in-house and through trusted suppliers:

- Zinc plating

- Chrome plating

- Nickel plating

- Black oxide

- Anodizing

- Electropolish

- Food grade polishing

- Tumbling

- Bead-blasting (for small parts)

- Sand-blasting (for small parts)

Differences Between CNC Milling and Turning

There are distinct differences between CNC turning and CNC milling. CNC milling uses a cutting tool that moves along a stationary workpiece to remove raw material. During CNC turning, the workpiece rotates while the cutting tool moves along the material to create the shape. CNC turning is suitable for projects that require cylindrical parts. CNC milling should be used for parts that do not require cylindrical shapes and can be used as a secondary finishing operation to add definition. Complex parts that require prismatic and cylindrical features may use a combination of milling and turning.

What is CNC Milling?

CNC milling is an automated machining process used to create 2D and 3D CNC parts by removing material from raw materials. Shops use CNC milling machines to save time and increase manufacturing efficiency.

To make a CNC milled part, a block or sheet is placed on a table beneath a spindle that holds a cutting tool. A computer selects the tool used, the rotational speed, the vertical movement of the spindle, and the horizontal movement of the table. This allows loaded tools such as drills, taps, and end mills to remove portions of material to create the shape.

Types of CNc Milling Operations

Milling is a versatile process capable of producing a wide variety of part designs and features, such as grooves, threads, chamfers, and slots. Common CNC milling operations include:

Face Milling

In face milling operations, the CNC cutting tool’s axis of rotation is perpendicular to the workpiece surface. Specially designed face milling cutters consist of teeth on the face and peripheral teeth to cut high-quality flat surfaces and contours. Both horizontal and vertical CNC milling machines are compatible with face milling operations.

Plain Milling

Face milling, also known as flatbed milling or face milling, requires the CNC cutting tool’s axis of rotation to be parallel to the workpiece surface. The teeth run along the perimeter of a face mill, and wide and narrow cutters are used depending on the application. Wide cutters can cut larger surfaces, while narrow cutters are good for deeper cuts.

Form Milling

Form milling entails cutting irregular contours, surfaces and profiles and is often used to machine wide faces and curved surfaces. These operations use specially shaped milling cutters or fly cutters that can produce unique shapes, including concave and convex surfaces. Form milling is often used to produce semi-circular and hemispherical surfaces for complex part designs.

Angular Milling

Angled milling, or angular milling, runs the axis of rotation at an angle relative to the workpiece surface. Single angle milling cutters are used for angular milling. These cutters are capable of producing grooves, chamfers and serrations, as well as other angular features.

Industries We Serve

We have a knowledgeable and skilled workforce ready to meet your needs. We are able to meet the needs of various industries, including:

Automotive Industry

Aerospace Industry

Consumer Goods

Medical industry

New Energy Industry

Industrial Machinery

Start Your CNC Milling Project Today

Xtmade precision CNC milling shops are trusted by businesses across a wide range of industries that need custom machined parts. Contact us today or get started on your project.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…