On-demand Custom

CNC Machining Services

With industry-leading advanced equipment and experienced processes, we provide a full range of precision CNC machining services centered around meeting your needs and budget.

Our Advantages In Custom Manufacturing

Do you have unique custom manufacturing needs? Complex part geometries? Strong materials? Tight tolerances? Xtmade has the CNC machining technology and expertise to take on challenging jobs, which is one of our core competencies. If you need a partner who can meet your needs. Please contact us, we look forward to growing with you by providing our CNC machining services.

100K+ Mass Production Machining

On Demand CNC Machining Services

Xtmade provides custom CNC machining services for engineers, product designers, and more. Our CNC machining technology can meet your precision machining requirements. Our state-of-the-art machines are carefully maintained and updated to ensure that we can provide the precision you need in every project. We specialize in low-volume high-precision machining, prototype parts, and complete assemblies, seamlessly integrating our machining expertise and engineering skills with your design concepts to provide cost-effective solutions that meet our customers’ unique needs. Our skilled team uses advanced technology to provide high-precision parts with consistent accuracy. Whether it’s a low-volume production or a complex prototype design, we have the expertise to meet your needs. Our focus on timely delivery and strict quality control ensures that every part meets your specifications.

Our Capabilities

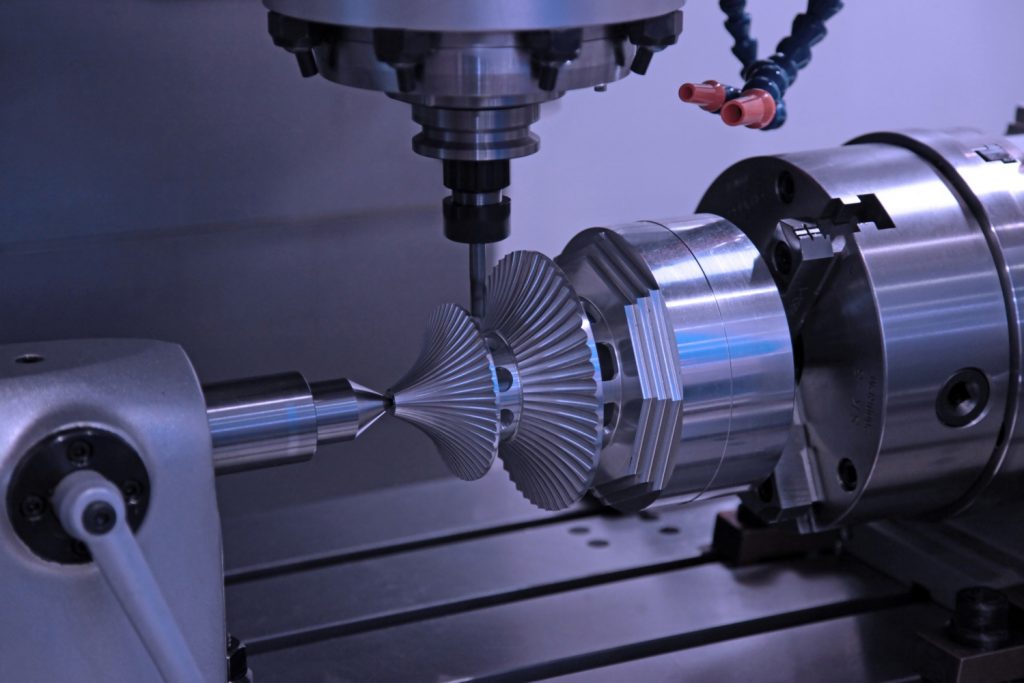

Our machining capabilities include contouring, slotting, drilling, boring, turning and threading. Our CNC machining centers feature 5-axis capabilities, allowing for complex milling of complex parts while maintaining true positional tolerances of ±.001”. Length and diameter tolerances can be maintained to ±.001” and are verified with precision CMM equipment. In addition, we offer contract manufacturing services, handling large and small projects with equal proficiency. Prototype tooling services provide your business with the opportunity to create, test and refine designs prior to production.

Types of CNC Machining Services

We offer CNC machining services including milling, turning, and can also provide custom designs and prototypes. With state-of-the-art equipment and experienced technicians, we can help you turn your ideas into reality.

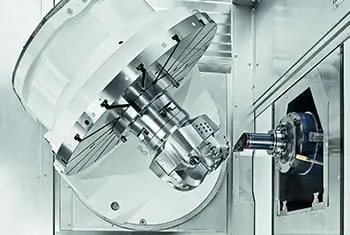

5-Axis CNC Machining

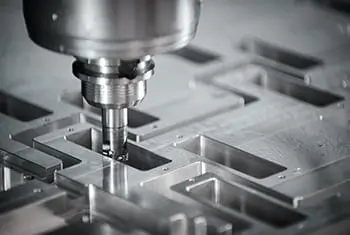

CNC Milling

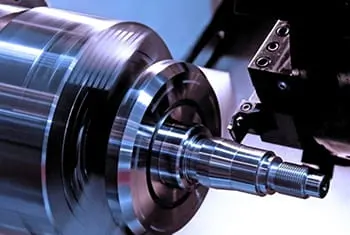

CNC Turning

Our tolerance standards

Unless otherwise specified, tolerances on metals will be held to +/- 0.005″ (+/- 0.127mm) per ISO 2768. Plastics and composites will be held to +/- 0.010″. Xtmade can manufacture and inspect tight tolerances, including tolerances closer than +/- 0.001″, to your drawing specifications and callouts. In addition, we can accommodate any standard thread size. We can also machine custom threads; these require a manual quote review.

Differentiated Custom Machining Services

Whether you need a few parts or over 10,000 end-use production parts, CNC machining is the ideal manufacturing process for you. Our high- and low-volume production capabilities produce CNC prototypes and proof-of-concept parts with short lead times.

Prototyping for Validation and Testing

Prototyping allows your design team to closely simulate the appearance, function, and material properties of the final product. In addition, testing the fit and manufacturability of components helps validate and improve designs. We offer professional custom CNC services to ensure quality and accuracy of delivery.

Custom machining of low-volume parts

Produce low-volume of custom parts with CNC machining. Its accuracy and repeatability, process flexibility, and wide range of material options help you get products to market faster. We have the capabilities and experience to provide efficient custom CNC machining services at an affordable price, helping you reduce production time.

Ready to Get a CNC Machining Quote?

CNC Machining Materials

Xtmade offers you a wide range of material selection options to complete prototypes and production runs of custom parts.

Metals

- Aluminum

- Copper

- Brass

- Bronze

- Steel

- Stainless Steel

- Magnesium

- Titanium

Plastics

- ABS

- MMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- HDPE

- HIPS

- FR-4

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- PTFE (Tefon)

- UPE

- Bakelite

Post-processing and surface finishing options

We support one-stop CNC machining of surface finishes to eliminate any defects that may hinder functionality and meet the visual and functional requirements of any design. If you require a custom surface finish not included in this list, please contact us.

Finishes for Plastic

- Standard Machined

- Finish

- Flame or Vapor

- Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel

- Plating

- Silver Plating

- Gold Plating

- Painting

Production Capabilities

When you are considering working with a company to help you get custom services, it is important to know what types of facilities they have. Our CNC machining facilities have evolved over time as we have invested in the technology and team required to provide advanced CNC machining services. As a result, our CNC machining capabilities are able to meet demanding requirements. In addition, our CNC department can design and manufacture parts to meet your unique requirements and specifications. We can also program parts with complex shapes, tapers, and complex compound contours, and can produce machined parts in a variety of materials to meet your application. We are a very modern CNC machine shop that can handle any order quantity. Our facilities are fully equipped to produce your parts economically. With our state-of-the-art facilities, you can be sure to get the precision and quality you need.

Quote Now to Start Your CNC Machining Project

Complete CNC machining services from prototype to product, ensuring high quality delivery and competitive pricing.

Precision Machining

What is CNC Machining?

CNC machining is the use of high-speed cutting tools to automatically create designs from stock metal or plastic. Standard CNC machines include 3-, 4-, and 5-axis mills, lathes, and planers, and the way parts are cut varies. The workpiece may be stationary while the tool moves, the tool may be stationary while the workpiece rotates and moves, or the tool and workpiece may move in sync. Skilled machinists program CNC machines based on CAD models to cut precise and repeatable tool paths for custom parts.

Advantages of CNC Machining

- Rapid Prototyping: CNC machining is ideal for creating rapid prototypes, allowing for rapid design iterations and testing prior to mass production. This reduces development time and costs.

- High Precision and Repeatability: CNC machines have excellent accuracy and consistency, which is critical for complex parts and tight tolerances. This means reliable performance and efficient assembly of the final product.

- Wide Range of Materials: CNC machining can process a wide variety of materials, from soft plastics to high-strength steels and exotic alloys. This versatility allows for parts to be created with optimal properties for each application.

- Complex Geometry Manufacturing: CNC machining excels at creating complex shapes and features that are difficult or impossible to achieve with traditional machining methods. This opens up design possibilities and allows for the production of more functional and innovative parts.

- Automation and Efficiency: CNC machines are computer controlled, allowing for unattended operation and reducing human error. This can increase production speeds, reduce labor costs, and achieve consistent quality output.

Alternatives to CNC Machining Services

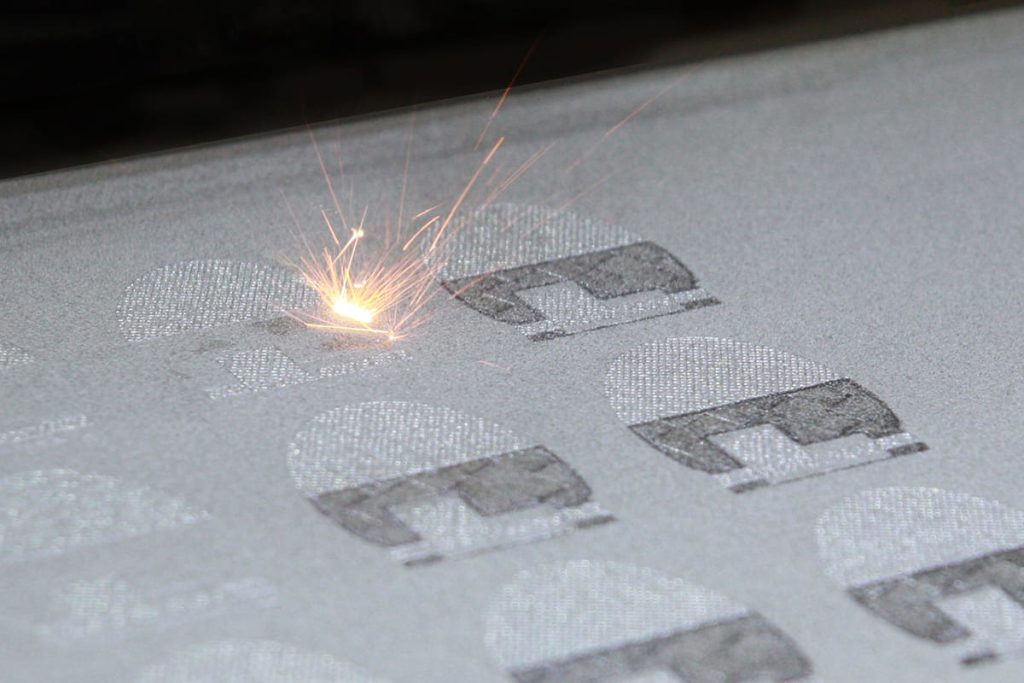

While CNC machining services are suitable for manufacturing a wide range of materials and part types, they also have limitations. For example, it cannot be used to create internal features such as internal cavities or conformal cooling channels. However, these can be custom manufactured through additive manufacturing methods such as DMLS, metal 3D printing, etc. In addition, if you need to machine certain types of flat workpieces, it may be more efficient to use sheet metal production processes such as laser cutting, water jet cutting, wire cutting, etc.

Design Guidelines for CNC Machining

Optimize your design and make your parts manufacturable using our CNC machining guides. Our experts can provide DFM design feedback for your custom machined parts to achieve your design results.

- Inside corner radius: Design inside corner radius to be 0.020” – 0.050” larger than standard drill bit size. Follow a drill bit diameter to depth ratio of 1:6 (1:4 recommended) as a guide for inside corner radius.

- Undercuts: Always design undercuts to standard size and away from corners so the cutting tool can access them.

- Threaded hole depth: Provide tool clearance slightly greater than the threaded hole depth to ensure full threads.

- Text: Minimum width is 0.5mm and depth is 0.1mm. Standard text can also be created using laser marking.

- Avoid thin walls: Minimum thickness should be 0.5-0.8mm for thin-walled metal parts and 1.0-1.5mm for plastic parts. If the wall is used to support action or taller features, the wall thickness should be increased to avoid vibration during CNC machining.

- Avoid deep grooves, grooves and holes: Keep the cavity depth 3 – 4 times the tool diameter or the groove depth less than 4 times the feature width. For blind and through holes, the maximum recommended depth is 4 times the diameter, the minimum hole diameter is 1 mm, and it is recommended to design standard size holes.

- Make the internal radius as large as possible: We recommend that the radius should be greater than 1/3 of the machining depth. The best approach is to relieve the internal corners or allow as large an internal radius as possible on the mating component design and use the same radius on all internal edges.

Why choose Xtmade as your CNC machined parts supplier?

Our company is here to serve you, from initial planning and concepts to prototyping and refinement, to providing the components you need to succeed. Our team is accustomed to handling jobs of all types and sizes. When we work with you, our goal is always to provide our customers with custom solutions to meet their precision CNC machining needs. With a high degree of flexibility and responsive service, we have the equipment and personnel to complete precision CNC machining projects on time, on budget, and to quality standards.

Industries We Serve

We provide CNC machined parts to companies in various industries around the world and are recognized by customers from all walks of life around the world.

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Ready to Get a Quote?

From design to prototyping to production, Xtmade is always ready to turn your ideas into reality and provide advanced manufacturing solutions suitable for your products.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…