CNC PROCESSES

5 Axis CNC Machining

With our custom 5-axis CNC machining services, you can get high-precision production parts with extremely complex geometries at an affordable price. World-class 5-axis CNC machines can produce precision parts quickly and to tight tolerances.

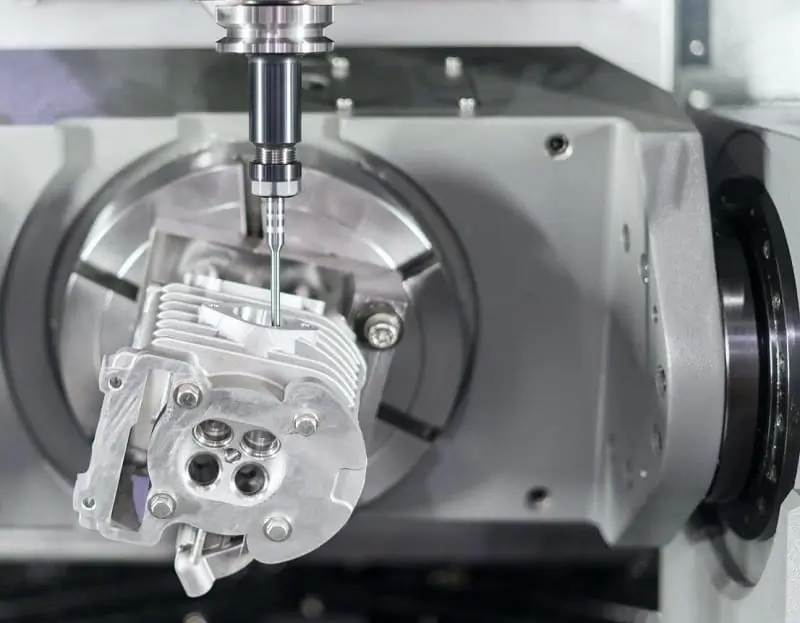

5/3+2 axis CNC machining

High Quality 5Axis CNCMachining Service

Xtmade’s CNC machine shop is equipped with high-quality 5-axis machining services to meet the unique needs of our customers. Whether you require custom parts for aerospace, automotive, or medical applications, we have the expertise and equipment to deliver exceptional results.

Our experienced team of machinists and engineers work closely with our customers to understand their specific needs and requirements. From the initial design stages to the final product, we are committed to providing exceptional service and quality. And, in addition to our 5-axis machining capabilities, we also offer a range of other machining services, including prototyping, rapid prototyping, and EDM machining. With our equipment and advanced technology, we are able to provide efficient and cost-effective solutions that meet the highest standards of quality and precision.

5-sided (3+2 machining) with simultaneous 5-axis

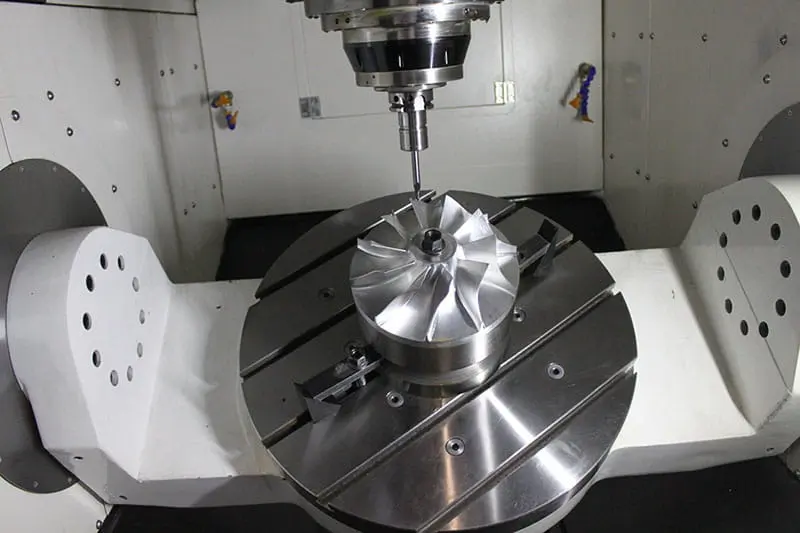

With our five-axis machining services, we can machine complex geometries with extremely high precision and accuracy. For extremely complex and multi-faceted parts, our advanced five-axis machines can process efficiently and flexibly through five-axis linkage, allowing shorter and stronger cutting tools to improve stability, maintain accuracy and obtain good surface quality. Xtmade provides five-axis CNC parts machining services to customers around the world, covering industries such as aerospace, automotive, marine, machinery, medical, energy, electronics, etc. Whether it is metal or plastic material, whether it is prototype design or Low volume production, the advanced equipment in our factory can meet your needs. We have the processing capability to achieve a tolerance accuracy of 0.002mm and can provide a complete test report. You can entrust your project to us with confidence

3+2 Axis CNC Machining

3+2 axis is another form of 5-axis CNC machining. When the cutting tool is not moving along the X, Y, and Z axes, the machine can rely on the 4th and 5th axes (adjusting the angle of the cutting tool). This form of 5-axis machining is generally slower than simultaneous 5-axis CNC machining, but can produce stronger parts and longer tool life.

Simultaneous 5-axis CNC machining

Simultaneous (or continuous) 5-axis CNC machining is an advanced CNC 5-axis machining method in which the machine tool can be adjusted continuously without interruption, allowing five axes of motion to machine parts with complex designs such as curved surfaces, irregular shapes and deep cavities. Simultaneous 5-axis CNC is very efficient because the cutting tool can move continuously without interruption.

What ls the Difference Between 3-Axis and 5-Axis CNC?

The difference between 3-axis and 5-axis CNC machining lies in their capabilities and the level of precision they offer. 5-axis CNC machining is considered the pinnacle of computer numerical control technology and has revolutionized the manufacturing landscape. Unlike 3-axis machines, which control the machine along the X, Y, and Z linear axes, 5-axis machining adds two additional rotational axes. This advanced technology can create parts with unique shapes with unmatched precision.

A key advantage of 5-axis CNC machining is its ability to perform a comprehensive dimensional analysis of the material through 5-axis positioning machining. This comprehensive analysis helps produce components that meet quality standards and are accurate. 5-axis machining offers unparalleled versatility compared to traditional 3-axis and 4-axis machining options. By machining a component from three axes simultaneously, complex parts can be produced, increasing efficiency and reducing production time.

Explore our advanced precision machining capabilities

Xtmade has expanded its range of subtractive manufacturing and CNC machining services with large 5-axis CNC machines to better provide powerful machining capabilities in demanding and complex applications.

Machining Processes

Boring, broaching, countersinking, counterboring, cutting, drilling, facing, hobbing, internal profiling, knurling, milling, parting off, grooving, profiling, reaming, spline, tapping, threading (external, internal), turning (profile, form, taper, straight thread) and thread milling.

Materials

With advanced manufacturing technology and extensive experience, our 5-axis machining services team can create unique prototypes and components for you using a wide range of metals and engineered plastics. We provide quotes and material reports for over 100 metal and plastic materials.

- Aluminum

- Copper

- Brass

- Stainless Steel

- Titanium

- Plastic

Surface Treatment

Xtmade can provide a large number of surface treatment options to improve the surface quality of parts for 5-axis machining services. Applying these surface treatments based on the purpose of the part, we can effectively improve appearance, surface roughness, hardness, corrosion resistance, etc. The following are some of the surface treatment applications we commonly use.

- Machined effect

- Sandblasting

- Anodizing

- Powder coating

- Plating

- Polishing

What is 5-axis CNc Machining

The cutting tool on a 5-axis CNC machining center can move on five axes (usually only three). Compared to 3-axis CNC machines, where the spindle can move up and down, left and right, and forward and backward, 5-axis machines have an extra axis when working: the table swings left and right on two different axes, or the spindle itself rotates around one axis. This allows the cutting tool to approach the workpiece from countless angles and remove excess material, so parts with highly complex shapes can be manufactured. 5-axis CNC machining can also reduce the number of setups required, and automated equipment eliminates the need for machinists to manually adjust the workpiece because the cutting tool can easily reach more positions. This makes the entire machining process very fast.

Benefits of 5-Axis CNC Machining

With our 5-axis CNC machining services, customers can experience numerous benefits that significantly increase manufacturing output.

- Improved accuracy and precision: 5-axis CNC machines operate with greater precision than traditional 3-axis CNC machines. More complex parts and assemblies can be machined.

- Reduced lead times: Production speed is important for any project, and the ability to automatically position cutting tools on a 5-axis CNC machine means faster cycle times and potentially higher production throughput.

- EASY SETUP: 5-axis machines allow all parts to be set up in one go, even those with complex geometries, resulting in faster production, fewer errors and lowest operating costs.

- Increased complexity: One of the main advantages over 3-axis machines is that you no longer need to remove the workpiece during the manufacturing process. Complex angles and geometries can be machined efficiently and with high precision.

- Improved surface finish: Materials are held more tightly on 5-axis machines, which means better surface finishes for even the most complex parts. In this setup, tighter angles are achieved through an improved drilling process.

Industries We Serve

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Put Your Parts Into Production Today

5-axis machining delivers greater precision and speed for the most complex parts, providing high-quality machined parts that meet the needs of a wide range of industries. To learn more about our 5-axis machining capabilities, or to get started on your next machining project, contact the experts at Xtmade today.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…