Additive Manufacturing

3D Printing Service

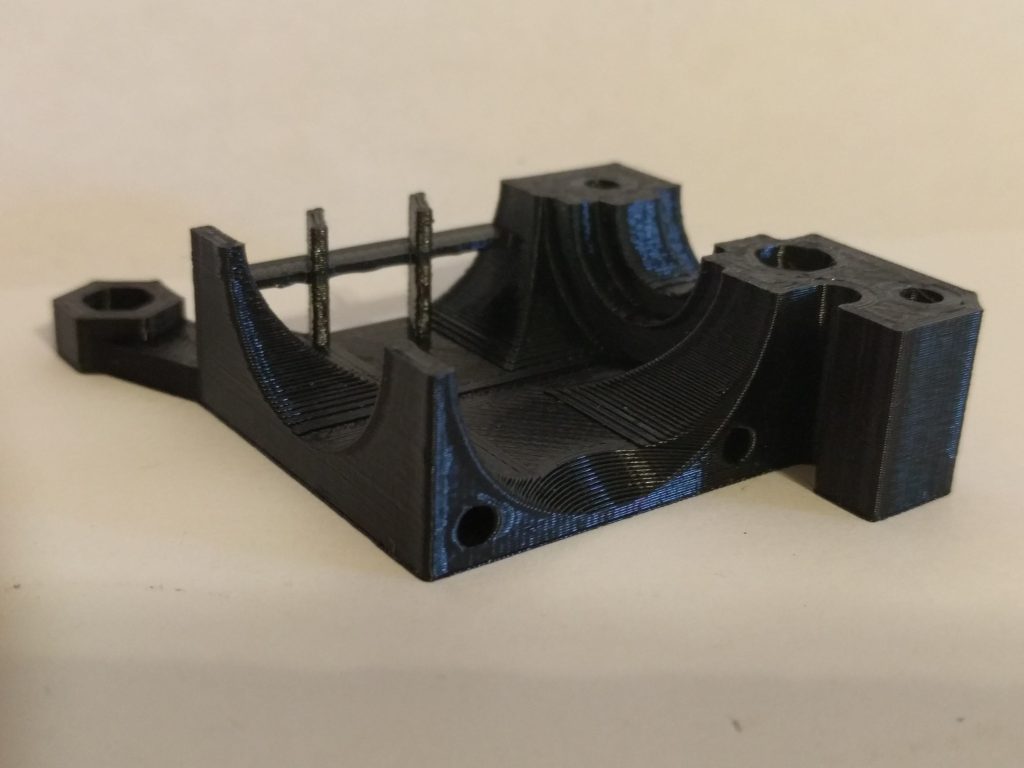

3D printing is an efficient and cost-effective way to produce parts. We can print both high-volume and low-volume metal or plastic parts, helping you perfect your prototype before committing to production. Contact us today for an instant quote.

Advanced on-demand manufacturing

Your preferred 3D printing service provider

Our online 3D printing services enable you to print custom parts on demand. We offer a variety of 3D printing technologies to transform your 3D files into plastic, metal and elastomeric parts. With our in-house 3D printer facility, we have the perfect capabilities to reliably deliver parts within days. In addition to a wide range of material options, we also offer a variety of post-processing options to improve appearance or enhance mechanical properties. With years of pioneering experience from our team of engineers, we offer metal and plastic 3D printing services and multiple material options for a variety of applications, whether small or large, simple or complex, prototype or production. Our experts work closely with your team from identifying and evaluating 3D printing candidates to exploring design improvements and cost savings.

3D Printing Service Types

From carefully designed prototypes to final production delivery, we provide best-in-class 3D printing solutions.

Metal 3D Printing

Stereolithography (SLA)

Selective Laser Sintering(SLS)

Multi Jet Fusion (MJF)

PolyJet

Carbon DLS

From concept to end-use part manufacturing

Xtmade doesn’t just produce custom parts, we provide tailor-made solutions for your projects. Partnering with us, you’ll get on-demand 3D printed parts and customized workflows to fit your manufacturing part needs, advanced verification and validation capabilities like First Article Inspection (FAl) or Production Part Approval Process (PPAP), and three state-of-the-art additive ecosystem facilities. Our suite of secondary and finishing services ensures your parts not only meet but exceed your exact specifications. From design to delivery, our 3D printing services help customers realize complex designs and parts through additive manufacturing, providing customers with precision, reliability, and unmatched quality. Choose us for a seamless journey from concept to creation.

Materials for 3D Printing

Since there are a wide variety of 3D printing materials to choose from, it’s important to make sure you choose the right one for your project.

SLS

- PA 2200

- PA12

- SLS TPU

MJF

- PA 12

- PA 11

- Glass filled PA 12

- Full Color PA 12

SLA

- High Temp TS

- Imagine Black

- Proto Plus

- Smooth GP

- Tough Plus

- Tough Resin Green

- Transparent Plus

- WaterTight Proto

SLM

- Aluminum AISi10Mg

- Stainless Steel 17-4PH

- Stainless Steel316L

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

- Titanium

plastics

- ABS

- Nylon

- N6 Carbon Fiber

- N12 Carbon Fiber

- PLA

- PETG

- PC

In-house Post Precessing

From beautifully designed prototypes to strong final production components, we have the solution. Xtmade has a wide range of tools and machines to remove support material from 3D printed parts. We use soluble support materials and can create complex geometries. We can also handle light 3D print post-processing including sanding, polishing, clear coating, marine epoxy coating (for waterproof FDM), and adding thermoset inserts. For larger printed parts or more specific post-processing techniques, we have you covered.

What can you create with Xtmade’s custom 3D printing services?

Xtmade offers a comprehensive range of additive manufacturing services to meet a variety of application needs. Whether you need a single prototype for rapid product development or a complex and durable part for mass production, our online 3D printing services can help you manufacture components quickly and more cost-effectively. This can speed up your innovation cycle, allowing you to focus on creating breakthrough products.

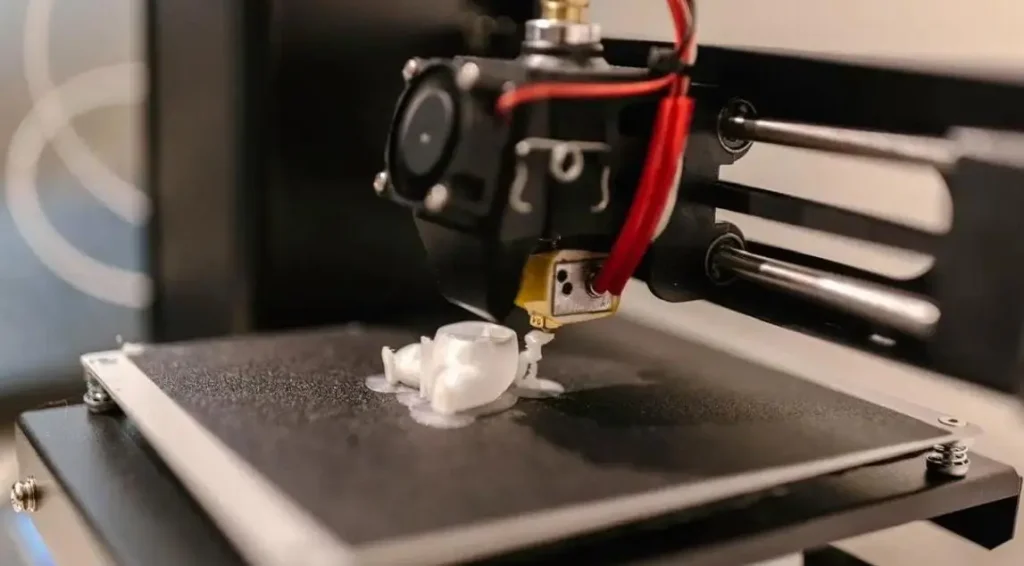

What is 3D printing?

3D printing is an additive manufacturing process for rapid prototyping! It is a versatile manufacturing process that is an alternative to traditional manufacturing methods and techniques. It is ideal for rapid prototyping, custom complex parts, and low-volume production. 3D printing is affordable and can be used when part designs have complex geometries that cannot be manufactured using other processes. Another advantage is that it has a wide range of applications, and this method can be used for products in any industry.

Advantages of 3D Printing

Layer-by-layer printed parts offer numerous advantages, opening up design possibilities that were previously unattainable through traditional processes such as injection molding, CNC machining or casting.

- Complex, organic geometries with limited impact on part cost

- Assemble multiple components into a single part

- No upfront tooling costs

- Rapid production of parts within 24 hours Internal features for advanced heat transfer and flow applications

Industries We Serve

Additive manufacturing can be used for rapid prototyping as well as large-scale industrial fields such as aerospace, medical, and automotive.

Automotive

Medical

Aerospace

Consumer products

New Energy

Industrial machinery

Ready to start making custom 3Dprinted parts?

Upload your 3D CAD file to get a quote for your 3D printed design. If you have any questions about the quote or design, you can work with our engineering team who will help you through the process.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…