Energy

Get high-quality manufacturing services for your custom energy prototypes and production parts. Produce on demand at competitive prices, get products to market faster, reduce risk, and streamline production processes.

Contract Manufacturer of Custom Parts for the Energy Industry

Xtmade is a leading contract manufacturer providing a full range of product design, manufacturing and assembly solutions to OEM of innovative green energy equipment and technologies. We support comprehensive manufacturing from product development, manufacturing and assembly to new product prototyping. With a team of highly skilled engineers and machinists, our facility is fully equipped to handle a wide range of complex parts and applications, meeting a variety of industry standard requirements. We also have a dedicated supply chain team that works closely with key industries to ensure efficient production and timely delivery.

Energy Prototyping and Manufacturing with Xtmade

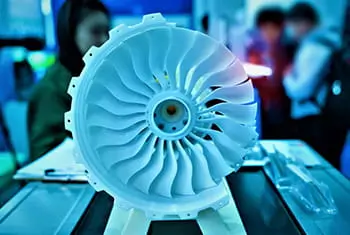

The energy industry produces fuels and fuel-based products, such as oil and gas, which require complex and innovative machines to withstand the rigors of deployment. At Xtmade, we have years of experience prototyping and manufacturing parts for energy industry clients, from solar panel casings to refinery parts.

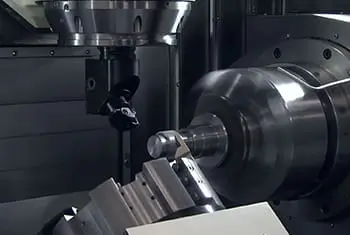

Innovation and the need for fast production and higher quality products are the main factors driving the energy industry forward. At Xtmade, we provide services such as rapid prototyping as well as CNC machining and sheet metal fabrication to our energy industry clients. Our team of experts has the knowledge and skills to help turn new product concepts into reality.

Our custom machining capabilities for the energy industry

Solar Panel Manufacturing and Processing The alternative energy industry requires a wide variety of production capabilities to manufacture critical components. At Xtmade, our high capacity and equipment diversity allows us to meet the needs of complex alternative and renewable energy projects. Some of our current projects for the industry include metal fabrication services for hydrogen and wind energy (turbines), as well as prototyping and production of electric vehicle (EV) parts.

As a turnkey manufacturing supplier to the energy industry, we work closely with leading brands in the new energy industry to produce critical components for alternative energy applications. The industry requires manufacturing suppliers that can adapt to the pace of the industry. Xtmade offers instant quotes, design, development, and production capabilities that perfectly blend the short-term requirements found in alternative energy projects.

Our Manufacturing Services

Xtmade offers a wide range of manufacturing capabilities, ideal for rapid prototyping and custom mass production orders. With our own factories and extensive China manufacturing network, we are able to efficiently deliver complex and high-quality parts.

Energy manufacturing materials

All of our manufacturing processes offer a wide range of material choices. Listed below are some common choices for energy projects.

- Inconel

- Stainless steel

- Aluminum

- Titanium

- PEEK

- PTFE (Teflon)

Applicable Finishes for energy industry

Xtmade offers a wide range of high-level surface finishes. We have listed only some of the common surface finish options. There are many more surface finish options for custom parts for the energy industry.

- As machined

- sanding & Polishing

- Sand, Bead Blasted

- Painted

- Powder coat

- Anodized

- E-Coating

- Nickel Plating

- Chromed

- Zinc Plating

- Chromate conversion Coating

Applications

From solar panel components to wind turbine parts, valves and more, Xtmade efficiently manufactures parts for the energy industry. Our combination of custom manufacturing solutions and quality management systems helps us bring your parts to market quickly and efficiently.

- Prototypes

- Solar panel parts

- Pipes

- Housings

- Jigs and fixtures

- Heat exchangers

- Battery components

- Ducts and ventilation

- Valves

- Generator components

- Frames

- Machine and tool parts

- Automation parts

- Replacement parts

- Moving parts

- Casings

- impellers

- Pumps and accessories

- Conveyors and conveying equipment

- heavy construction vehicles and equipment

- Parts for tractors, bulldozers, forklifts

- Turbine components

From Prototyping to Production

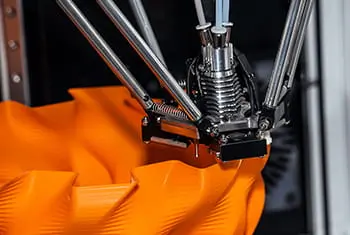

Prototyping

Bring your early designs to life with prototypes made from production-grade materials. Our process enables you to evaluate and optimize your designs, ensuring they are fully functional and ready for testing.

Engineering Validation & Testing

After rigorous engineering testing and validation of performance standards, you can quickly and easily make changes to your product prototype. Our functional prototypes are designed to simulate the final product, giving you a clear visual representation of your design so you can easily identify any potential issues.

Design Validation & Testing

Accurately evaluate the performance, functionality, and aesthetics of your energy products. Save valuable time and resources by making design improvements during the prototype phase. Our dedicated design team provides in-depth feedback on the manufacturability of your prototypes, helping you evaluate their performance and appearance.

Production Validation & Testing

Streamline your designs for mass production with our production-grade manufacturing capabilities and expert quality control. Gain insight into your product designs with expert feedback from our technical team. This enables you to evaluate the manufacturability and suitability of your energy components and make ultimate improvements to your streamlined production process.

Volume Production

Easily enter volume production with rapid delivery of end-use parts and seamless integration of your quality standards into Xtmade’s manufacturing process. Take your custom energy product manufacturing to new heights with our cutting-edge manufacturing technologies. Our team of experts is dedicated to ensuring your products meet quality and performance requirements, reducing costs and shortening delivery times.

Ready to get a quote for machining energy industry parts?

You design, we manufacture, turning your ideas into products.

Latest News

Xtmade team summarizes technical issues related to CNC machining

Xtmade team summarizes technical issues related to CNC…